ERP Software for Scotch Industry

Overview

The art of whiskey making is a centuries old tradition. From Europe, where the ancient alchemists first distilled the grain-based spirits, to the Scottish and Irish landscapes, Whiskey has come very far. This gave birth to whiskey’s distinct regional styles. Slowly with time, this tradition and the craft of whisky making passed down through the generations—embodying innovation of each era.

As the years passed, the demand for premium spirits has increased substantially. Today, it has become a preferred beverage choice among youngsters. These younger consumers may have different drinking preferences, making manufacturers experiment with new flavors and styles.

While the process of whiskey making has evolved to a great extent over the years, adapting to the current needs of consumers requires more research and development. Additionally, safety has become a prominent concern among consumers, making manufacturers adhere to stringent regulatory standards.

Concurrently, meeting the outstanding market quantity requirements is also mandatory. The challenge lies in managing all these tasks precisely, without ensuring zero deviation in the quality.

This is why companies these days have started turning towards adopting Enterprise Resource Planning Software. This completely automated and comprehensive solution helps businesses manage their crucial aspects effortlessly on the go. But before we dive into the ocean of ERP let’s first discover more about Whiskey and its manufacturing.

Would you like to learn more about our Scotch ERP Software?

schedule-a-discovery-call

Introduction Savoring the First Sip

The exact origins of Scotch (Whiskey) are traced way back in the 15th century. It was in England, more specifically Scotland, from where this beloved spirit had started travelling globally.

“According to the reports, in 2022, the value of Scotch Whisky exports was up 37% by value, to £6.2bn.” – Scotch-Whiskey.org.uk

The term “Whisky” is also derived from a Scottish phrase “Uisge Beatha”, which translates to “Water of Life.” Over the time, this phrase transformed into “Usky” and then to “Whisky.”

Their growing knowledge of distillation is further followed by another process named fermentation. This step significantly contributed to the gradual emergence of Scotch for the first time in Scotland.

From here, its popularity started increasing aggressively across Scotland, and then all over the world. Today, Scotland has around 140 active distilleries that are continuously evolving their operations with an aim to improve this iconic product “Scotch.” Ahead in this blog, several mysteries of Scotch are yet to unfold, keep reading the space to know.

What is Scotch?

By definition, Scotch is a distilled alcoholic beverage manufactured exclusively in Scotland. It is a perfect blend of water and malted barley which is fermented with yeast and then aged in the wooden oak barrels for years. The primary ingredients used in Scotch Production are Water, Yeast, and Cereal. Originally, Barley is the only cereal out of all, that is used for Scotch production. However, by the end of Eighteenth century, distilleries started replacing Barley with Wheat and Rye. But the secret that maintains the authentic taste of Scotch still lies in “Barley.

Processes Involved in Scotch Manufacturing

Peeling The Layers of Manufacturing Mystery

There are a lot of processes that goes into the production of Scotch Whiskey. The cereal Barley has to go through numerous stages from Malting, Mashing, Drying, Fermentation, to Distillation, and Maturation. Finally, the matured whiskey is bottled—giving it a final exquisite look.

The Process Flow of Scotch Manufacturing Includes

By law, all scotch whiskeys must be matured for at least for three years till it attains its original deep flavour profile before bottling.

Challenges Scotch Manufacturers Encounter

While we undoubtedly Savor every facet of a finely crafted Scotch whisky – from its captivating colour to its exquisite taste – it's essential to acknowledge and applaud the efforts that go behind the creation of this exceptional beverage. The makers of Scotch whisky must face a multitude of challenges throughout their journey in the pursuit of crafting this beloved spirit.

After this in-depth scrutiny of how these challenges and concerns impact the scotch manufacturing sector, it is evident that the road ahead presents both challenges and opportunities.

Yet, the task of overcoming the challenges and capitalizing on opportunities for success demands a robust technological support like an ERP for Scotch. With the help of ERP for Scotch industry manufacturers can effectively prioritize environmental sustainability, and secure profits.

Let us see how an ERP for Scotch helps manufacturers in this regard.

How ERP Helps Scotch Manufacturers Overcome These Issues

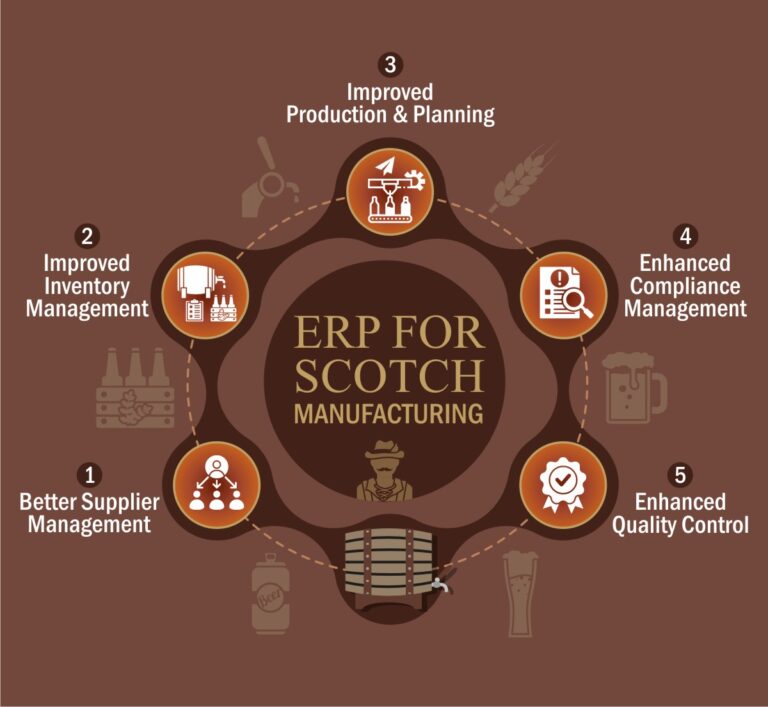

An ERP for Scotch manufacturing in Scotland is a comprehensive solution that manages all complex aspects of a business, including inventory, production planning, CRM, finance, and more. Let’s take a closer look at the benefits Scotch manufacturers get when they adopt ERP software to automate their operations.

Better Supplier Management

The production of Scotch depends on three fundamental ingredients: barley, Scottish water, and yeast. The quality of these raw materials will eventually decide the quality of Scotch. Therefore, effective supplier management proves to be of paramount importance in this process.

The supplier management functionality of a Scotch manufacturing ERP effortlessly eliminates this concern. It maintains a centralized repository of vital supplier information, encompassing contact details, certifications, and performance history.

This helps distilleries identify the right supplier for specific material, negotiate contracts, ensuring profitable and quality-driven purchasing process.

Improved Inventory Management

As discussed, the primary raw materials are barley, Scottish water, and yeast. Keeping these materials available in optimal quantities is the secret to uninterrupted and profitable production.

An ERP for spirit manufacturing helps Scottish manufacturers by enabling real-time visibility into their inventory levels at multiple locations. This way, distilleries can track their raw materials, barrels under ageing, their timelines, and finished products, facilitating informed decision-making.

Moreover, by analysing the historical data and trends, ERP software facilitates in calculating the precise requirements of raw materials to meet the upcoming demand. This prevents manufacturers from material losses and over stocking costs.

Improved Production and Planning

To ensure profitable and flawless production, distilleries must manage all the complex production processes efficiently. This involves multiple stages and ingredients to manage.

An ERP software for scotch manufacturing eases all these tasks by providing a centralized and common platform to manage production schedules, material procurement, and quality control checks.

Enhanced Compliance Management

As already mentioned above, distilleries need to follow various safety regulations. This includes labelling requirements, Geographic Indication Protection (GI), strict standards for barley and water, alcohol content, etc.

An ERP system’s compliance module helps manufacturers ensure adherence to all required safety standards. Its batch traceability feature tracks the complete lifecycle of products from origin to destination. This ensures that critical compliance related data is accurate and within permissible limits.

Furthermore, its robust record keeping capability facilitates in generating, storing, managing, and retrieving of documents such as regulatory certificates, qc reports, export/import documentation—ensuring that records are accessible and up to date.

Enhanced Quality Control

An ERP for scotch manufacturing industry in Scotland allows distilleries to implement a range of quality checks as per their product requirements. This functionality allows them to establish multiple checkpoints covering aspects such as colour, taste, aroma, Ph levels, etc.

This helps the Scotch manufacturers to ensure unwavering consistency throughout the production process—ultimately improving customer satisfaction.

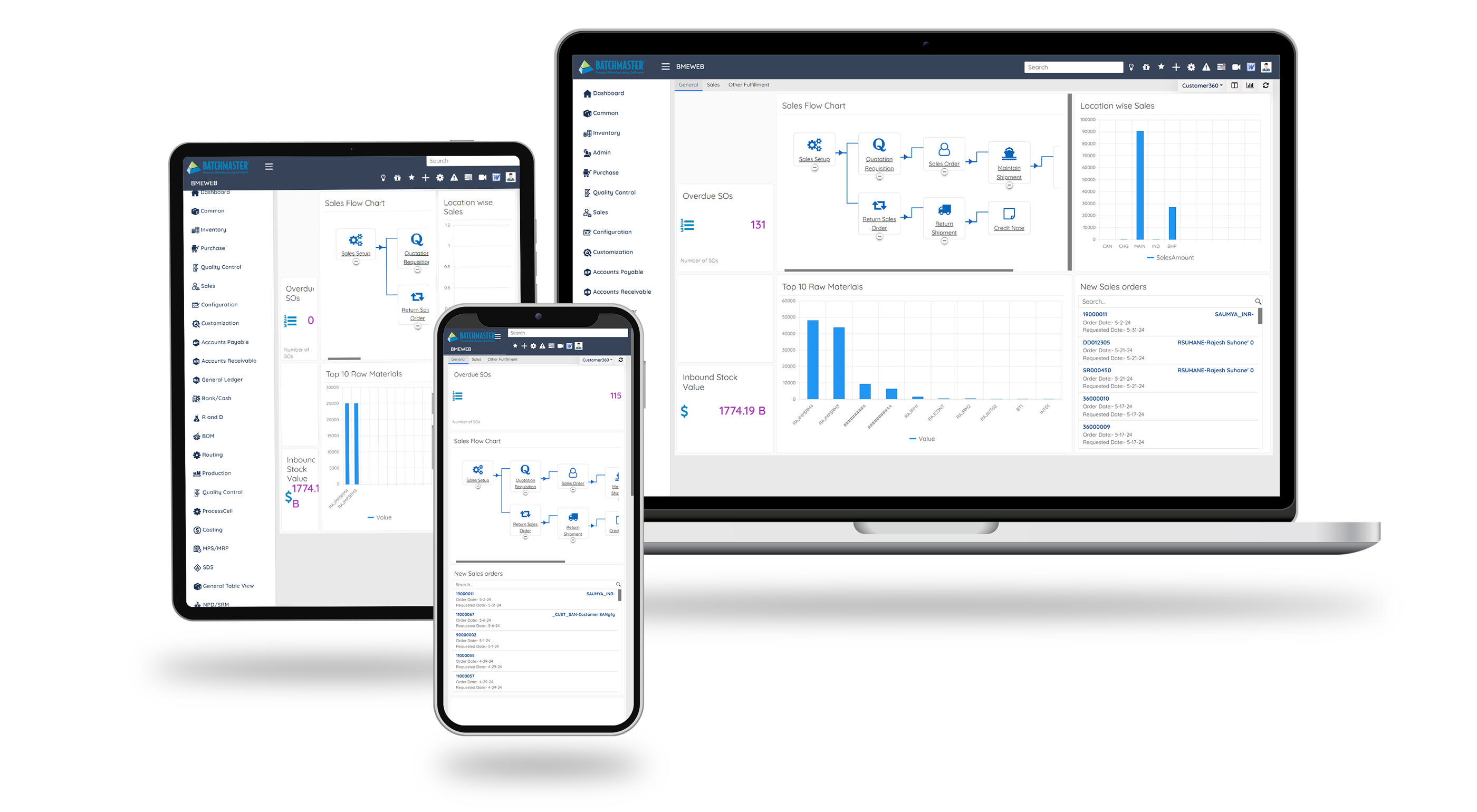

Why BatchMaster ERP is The Right Choice?

BatchMaster ERP is tailored to meet the unique production capabilities and requirements of your company. In addition to encompassing the aspects mentioned, it extends its capabilities to include accounting, label and boilerplate printing, and the streamlining of packaging workflows.

To discover the complete spectrum of our unique capabilities, get in touch with our team of experts to know more.

Looking To Find the Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

See BatchMaster ERP in Action – Book Your Free Demo Now

See how BatchMaster ERP streamlines compliance, enhances workflows, and drives faster, smarter food operations.