After two years of contraction, the UK domestic market has finally shown some sign of positivity. Output from manufacturing sector improved to a 20-month high in March 24.

Resilient labour market, robust wage increase has given some momentum to consumer’s purchasing power. Some relief in energy cost has also added to spending power of consumers.

Even if the domestic market is showing sign of improvement, the global market trend is not good for the UK. The foreign orders are still restricted.

The latest survey by Make UK‘s Manufacturing Outlook 2024 Q1 revealed that manufacturers in Britain will likely experience two years of sluggish growth. Forecasts show that the sector’s growth rate will remain at a low of 0.1% this year before increasing by 0.8% in 2025. This is just half of the expected GDP rate for the overall economy.

The manufacturing industry is very important for the UK economy, trade, and investment. UK manufacturing accounts for 51% of all UK exports. Manufacturing also accounts for 15% of total UK business investment and 64% of all UK business research and development.

At this junction, where the UK economy is swinging between growth and contraction, the manufacturers must incorporate ways to streamline their operations and improve their efficiency to reduce cost and losses. Cloud ERP can help them to achieve this goal.

In this blog we will try to know how cloud ERP can help manufacturers of the UK to streamline their operations for better growth but before that let us quickly understand cloud ERP and know its benefits.

What is Cloud ERP?

Cloud ERP is software that is delivered over internet. Contrary to its on-premises counterpart, it offers anytime, anywhere access to business related operations. Cloud ERP system can access and analyse massive amount of data in almost real time and is offered as SaaS (Software as a Service).

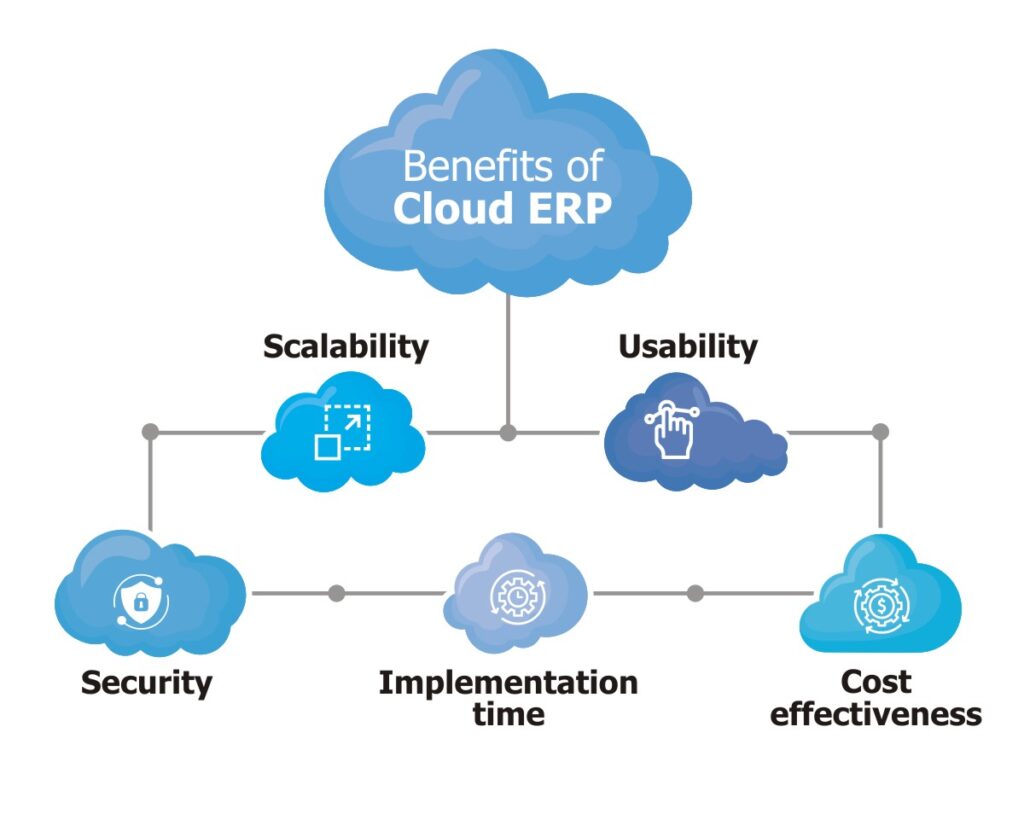

Key Benefits of Cloud ERP

With the change in business pattern, organisations realised that they need new age ERP software. They need an ERP software which can sync with their business needs and therefore organisations shifted to on Cloud ERP software. A Cloud ERP software is much different than its on premises counterpart. Let us discuss benefits of cloud ERP in short.

Scalability– A Cloud ERP is highly scalable. That means one can add as many numbers of users as one wants with ideally no modifications. Likewise, it can process massive volume of data in almost real time. It is much secured from cyber-attacks, and it gives more control over data.

Usability– Businesses are being very dynamic these days. C-suits require various data at their fingertips. They want to tap all possible opportunities. Cloud ERP software for manufacturing helps them to do so. It can be used from any internet enabled device at any time. Hence, it works beyond boundaries of time and location.

Cost effectiveness– Cloud ERP comes as software as a service (SaaS). It comes as a subscription model. That means there is no upfront software purchase cost involved.

Moreover, it does not require additional IT head counts or infrastructure as it can utilise existing infrastructure and already present workforce can be trained.

Implementation time– A cloud-based ERP software is faster to implement. As an on promises ERP software can take anything around 3-6 months or more (depending upon project size), a cloud-based ERP takes just few days/weeks to implement. That means, practically there is not much hindrance in day-to-day operations and organisation can achieve go live stage of implementation much faster.

It is worth mentioning here that among various cloud ERP software, BatchMaster Lite, a product of BatchMaster offers implementation cycle of just 21 days’ (depending upon volume of data).

Security– A cloud ERP is more secured than its on-premises counterpart. Data is secured at various locations and updates are automatic. This diversification of data makes data retrieval easier and faster, whereas auto updates keep the system secured.

After reckoning benefits of cloud ERP, let us switch the gears and understand its role in streamlining operations for manufacturing business.

How does cloud ERP software streamline operations for manufacturing business?

Manufacturing is a complex process. It involves various dimensions. To ensure smooth and timely production, every aspect of production should be well taken care of. The glitches must be resolved, bottlenecks must be cleared, and conclusions must be drawn from data points to get required output in time.

An ERP software manages various dimensions for smooth production. Here are some of them-

Inventory Management- A cloud ERP removes physical restriction of managing multiple warehouses by leveraging real-time connectivity. One can easily check and update inventory status, register warehouse movement right where they are happening. One need not to first record them manually at the location, and then come back to the place where on-premises ERP is kept to feed the details.

Cloud ERP software offers all time access to inventory which facilitates immediate decisions related to inventory. This immediate decision flexibility catalyses production speed, eventually improving the rate of order fulfilment.

You can run cycle count at a time which affects the business operations the least and if discrepancy found, one can rectify it immediately.

Supply Chain Management– How well do you know what’s happening in your factory right now? How much visibility do you have into your current operations, logistics, and inventory?

A cloud ERP can give you a real-time picture via a unified dashboard. With this modern cloud ERP, you can gain immediate, comprehensive visibility across your logistics and inventory in real time.

This increased visibility helps manufacturers to take immediate decisions and change strategy to tackle any disruption.

Suppose a product is stuck in bottleneck at shipping. Due to real time connectivity and accessibility cloud ERP offers, an alert of shipping bottleneck can inform customers about delay in shipment. Likewise, this visibility can help supply chain managers to ease out the bottleneck and sort the issues as soon as possible.

Order Management– Sales order can be generated via multiple platforms- e-commerce platform, sales channels, or customer service representatives.

A cloud ERP can capture various data at centralised location. All the concerned departments involved in fulfilling the order can access this data from anywhere in the world. Hence, with perfect coordination among teams, the order can be delivered in committed time.

Cloud ERP software for manufacturing jumps over the boundary of time & location and helps manufacturers to take timely actions which eventually makes customers happy.

For example, when a salesperson gets a lead, he can place an order from anywhere and at any time without being compulsorily in the office. This flexibility triggers the sales order process faster, which churns faster production and eventually faster order fulfilment to bring smiles on customers’ face.

New Product Development- Consider a scenario, where a client requests for some samples with his specifications. With the help of cloud ERP, the salesperson, customer care representative, or a consultant can immediately log in the request which can alert all the concerned departments, like R&D, inventory, finance etc.

Irrespective of time and location, the concerned authorities can act immediately to initiate R&D. Immediately after R&D department cracks the correct formula, samples can be created and can be sent for client approval.

Since all the departments are on the same page at each stage of new product development, communication is clear, and process is speedier. This collaboration of teams reduces time lag and keeps the organisation one step ahead in competition.

Production Planning– Production planning is crucial aspect of manufacturing. A manufacturing cloud ERP software possesses comprehensive production planning tool that allows manufacturers to plan and schedule efficiently.

It gives real-time visibility into shop floor, warehouses, demand and supply.

So, for any given point of time, an organisation has real time data about the machine capacity, available resources, available inventory etc. Accordingly, it can commit to the client or take necessary actions to fulfil the requirements.

In case of lack of real time visibility into these factors, commitments might fail which would eventually dent the reputation of the organisation.

Cloud ERP brings all these aspects under one platform helping make precise plan.

Production: A manufacturing cloud ERP provides real-time visibility into shop floor activities. Thus, without being present at the place of action, one can easily check the status of production, how much is being produced, and which materials are critical.

It also facilitates to check if inspection of the materials is done correctly, temperature and other parameters are maintained as per requirements. If any deviation from the standard is found, one can take necessary action. This ensures the quality of output and avoids rework and wastage.

Conclusion:

A cloud ERP software for manufacturing plays a pivotal role in streamlining operations for manufacturing business, therefore, selection of the ERP software is also equally important. The software that you select must have good reputation and experience, not to mention it must fulfil your requirements.

BatchMaster ERP has been serving manufacturing industries for last 30+ years and has earned great respect among process manufacturers across the globe. With more than 3000 implementations till date, the software has carved its niche in the ERP space.

With myriad functionalities, benefits and long industry experience, the software can be a great partner in your growth story. If you are a manufacturing organisation and looking for a cloud-based ERP to streamline your business, BatchMaster ERP can be a go to solution. To know more about BatchMaster ERP or discuss how it can fit in your requirement, please feel free to contact sales@batchmaster.co.in.