What made the world’s most un-sinkable ship brake? It was an iceberg submerged in the waters. The outer part of the iceberg was visible, but the hidden part wrecked the ship.

Chemical businesses are like that large ship. Most of the time chemicals that are not traced, not tracked, lying in shelves of inventory can become icebergs for Titanic-like chemical businesses. Unaware of the threats those lying inventory can pose, businesses keep sailing and reach to a point of no return.

The captain of Titanic didn’t have a system that could notify of the danger, but business leaders do. They have access to chemical inventory management software, a tool designed to manage chemical inventories effectively. The software can update stock levels, identify location and track chemicals stored in the inventory.

To know more about this software, stay tuned till the end.

What is an Inventory Management Software?

Inventory management software, also known as Inventory Management System, is a software that can track, organise, and oversee all inventory, as well as inventory related operations of an organisation.

An inventory management system aims to bring down inventory carrying costs and ensures sufficient stock is available to meet customers’ demands.

Why Does the Chemical Industry Need Industry-Specific Inventory Tracking Software?

Chemical industry, unlike other industries, comprises inventory items with diverse nature, like different potency, reactivity, hazard threats, volatility and so on. Handling these materials together is risky. Slight negligence or mistake in handling can turn out to be disastrous. Moreover, it can lead to compliance issues, safety threats, and other inefficiencies.

Besides, shifting consumer preferences and shortening product life cycles add extra layers of complexity to inventory.

To manage inventory of such a reactive and sensitive industry, chemical organisations must use chemical inventory tracking software. The software is designed to cater the specific needs of the industry.

These organisations can treat inventory materials with due care along with taking worker safety and environmental concerns in consideration by having industry specific software at their end. By having inventory carrying costs at their fingertips, organisations can strategize to optimise it.

Features of Chemical Inventory Tracking Software

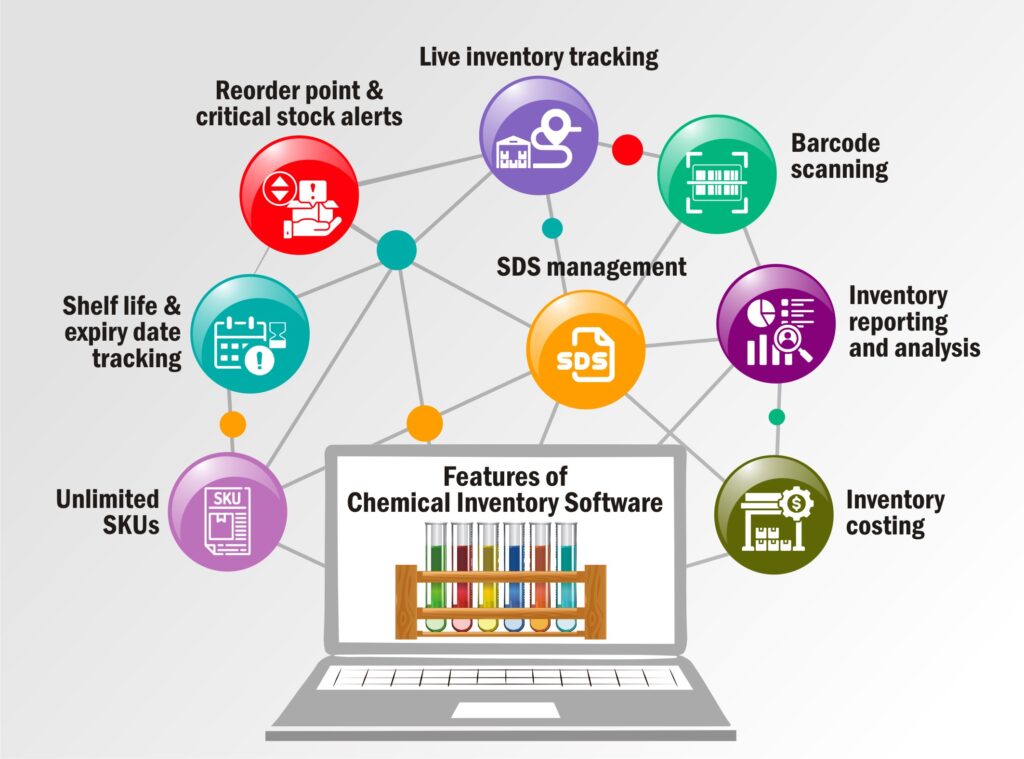

Chemical Inventory Management Systems have various features, and the list can be broader depending upon the software brand. But some of the common features are:

Live inventory tracking-

This software gives a fair idea of item location, stock level, and their costs. The software also updates data in real-time and instantaneously as and when inventory is consumed, replenished or in case of inventory transfer.

Barcode scanning–

Barcode scanning facility in inventory management enhances fulfilment accuracy and order-picking efficiency. Barcodes can be installed to stock items and can be scanned whenever they are moved. It can also be used to auto-update material location or quantity.

Inventory reporting and analysis–

Inventory reports show materials that are fast-moving or least preferred. Fast moving materials are indicators of the consumer preferences and choices. They can help organisations to make informed decisions about inventory items and purchase choices.

By having these reports and analysing patterns, an organisation can identify current trends and can anticipate future demands.

Inventory costing–

Inventory costing is an important feature of inventory management software. Many strategies and decisions depend upon the costing. A good chemical inventory management software must be able to:

- Update inventory costs real time

- Provide current view of inventory value- at various warehouses, regions or countries

- Should be able to track variable costs like courier cost, or labour cost.

Reorder point and critical stock alerts–

Inventory stock updates are useless if they don’t prevent stock outs. An inventory management software, therefore, must have provision to send alerts if stock levels touch a defined threshold value, popularly known as reorder point. By allowing to define a reorder point, inventory tracking software generates alerts and helps to stop stockouts.

Unlimited SKUs–

An inventory management software must allow to add as many SKUs as required. In other words, search for an alternative option if an inventory management software limits number of units that could be added or doesn’t support various units of methods or if it is not able to convert one unit to other instantly.

Shelf life and expiry date tracking–

A good inventory tracking software provides easy expiry date and shelf-life tracking and offers various issue methods FIFO (First In First Out) and LIFO (Last In First Out) methods. This ensures consumption of materials before they expire, hence prevents wastage.

Safety Data Sheet (SDS) Management–

Safety Data Sheet are essential documents containing information about hazards, handling and emergency measures related to chemical. Chemical inventory software can manage SDS to make sure that they are available to relevant person, as and when required.

Benefits of Chemical Inventory Management System

Automates manual tasks–

By having barcodes and RFID scanner, inventory stock taking, receiving and fulfilment are accelerated. Manually performing these tasks is time consuming and erroneous. By automating it, not only speed increases, but also chances of errors go down.

Greater visibility with real-time data–

Chemical inventory management software offer access to real time information to all SKUs.

Improved forecasting–

Correct analysis of data can provide better insights of trends. Better understanding of trends results in better forecasting.

Prompt decision making–

Analytics of inventory management software help in making data driven stock decisions. Control expenditure by reducing inventory and carrying costs.

Supports uninterrupted production–

Optimised inventory help in all time availability of raw materials to facilitate uninterrupted production.

Scale inventory as business grow–

As business grows, volume of data, number of facilities also grow. A good inventory tracking software must be capable of tracking the inventory flawlessly.

Environmental protection–

Efficient inventory management fosters responsible handling and disposal practices to reduce risk of environmental contamination. By ensuring proper waste disposal, organisations contribute to protecting environment and strive towards sustainability goal.

Regulatory compliance–

Chemical inventory software contributes to complying with various regulatory norms. It ensures that adequate precautions are taken, proper handling procedures and safety protocols are followed to minimise risk.

What to Look for in a Chemical Inventory Tracking System?

Besides above-mentioned features, following are some must have features for chemical inventory management software:

Compliance Capabilities-

Ensure the software supports specific regulatory requirements (e.g., OSHA, GHS, REACH). It must have features like automated SDS generation and regulatory reporting.

User-Friendly Interface-

The software must have intuitive design to minimise the learning curve for employees. A user-friendly design fosters easy navigation. Besides, customisable dashboards enhance utility.

Data Security –

Ensure robust security features like encryption, role-based access, and regular backups.

Support and Training –

The vendor must provide customer support, training program and documents or tutorials.

Mobile Accessibility-

The software should offer mobile compatibility for on-the-go access and updates.

Limitations of Inventory Management Software

Limited scope–

Inventory management software can be used to track, update, and manage inventory. It lacks functionalities of other important business critical areas like production, sales, formulation, QC etc.

Integration issues–

Inventory management software can have limited integration with other systems like ERP, CRM. Moreover, integrating with various disparate systems might affect the cohesiveness of the system.

Manual process for other operations–

Processes like procurement, financials, and sales may need to be handled manually or through separate software. This will increase operational complexity.

Chemical ERP: A Better Solution

Overcoming the limitations of inventory management software, yet providing all the benefits, a chemical ERP software is a perfect alternative. Considering manufacturing scenario, the industry specific ERP not only manages inventory, but also provides centralised data for all the departments of a chemical manufacturing organisation- procurement, sales, production, QC, finance, etc.

Following are some of the reasons that prove chemical ERP a better solution than a chemical inventory management solution:

In-depth reports and analytics–

Chemical ERP provides in depth reports and analytics not only of inventory data, but also of data from every department. This data gives a fairer idea of consumer preferences, cost involved, etc. Thus, organisation can strategies precisely based on data driven information and get competitive edge.

Better optimised inventory –

Chemical ERP has MRP/MPS capability. It plans production batches based on the demand and supply. This plan then becomes the food for material planning and an ERP calculates that too with complete precision for an uninterrupted production flow.

Risk mitigation–

ERP can minimise risk by tracking hazardous material, managing safety protocols, and ensuring proper waste disposal practices.

Cost efficiency–

While the initial investment in ERP is high, it eliminates necessity of multiple system which collectively can cost higher. Also, with single system at place, there is smoother process workflows and sharing of data. With availability of Cloud ERP, even the initial investment has gone down multi-folds making an ERP affordable and adoptable by businesses of all sizes.

No or minimum integration requirement–

Since ERP connects to all departments and have capabilities to manage inventory, production, finance, QC, sales etc., it does not require any other system to integrate with. For special requirements, if the need of integration arises, it is easier to manage and cheaper on pocket.

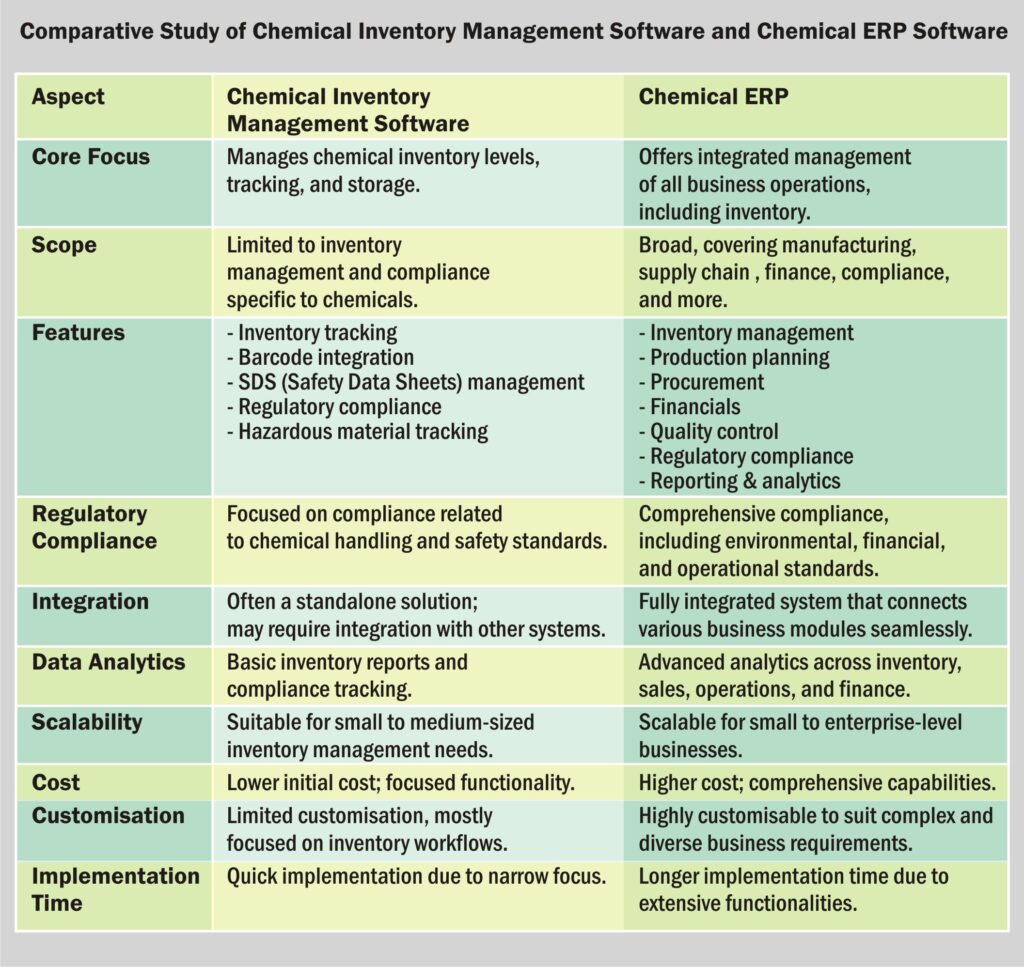

Comparative Study of Chemical Inventory Management Software and Chemical ERP Software

Why to Choose BatchMaster ERP for Chemicals?

BatchMaster ERP for chemical is an industry specific ERP software which caters to various micro-verticals of chemical industry. There are multiple reasons to choose BatchMaster ERP, some of which are as below:

Wide experience–

The software has been solving production challenges of chemical manufacturing organisations across the globe for last 40 years. BatchMaster has established itself as expert in the market, and the trust has been endorsed by various clients Y-O-Y.

Industry specific features–

The software is equipped with industry specific features like stability testing, HAZMAT bill of lading, VOC, SARA reporting, inventory management, containerisation, new product development, HMIS, WHMIS support for worker safety etc.

Comprehensive formulation modules–

The software not only offers formulation capability, but it also provides security to formulation data. Moreover, version controlling, purging of old formulae, formula costing calculation, application of what-if scenario, QC in formulation, side by side comparison of formulae, using various unit of measures, and many more capabilities make the formula management module more robust, and flexible to tackle any challenge and tap new opportunities.

Get eco-friendly products–

It helps to optimise usage of resources (man, machine, material) by reducing wastage and complimenting to good manufacturing practices. It even supports handling, maintenance and disposition of hazardous material along with generating supporting documents. This eventually supports sustainable production.

Work with existing financials- With BatchMaster ERP for Chemicals, continue with existing financials. It seamlessly integrates with Tally, QuickBooks, Sage, SAP Business One and other popular finance/accounting systems.

Adherence to regulatory compliance– Chemical industry is highly regulated. It must adhere to various national and international regulatory norms. BatchMaster ERP for chemicals help in adhering to these norms like OSHA, EPA, ISO, DOT.

Take a deep dive to know more reasons that make BatchMaster ERP for Chemicals an ideal software for the industry specific needs.

Wrap up:

To strive in a competitive market of such a highly regulated and sensitive industry, organisations must be fully equipped, and ready to face any challenge that the industry might pose. A chemical inventory management software helps to solve only inventory-related challenges whereas an industry specific ERP offers a holistic solution.

Face the turbulence of industry with confidence, make the best utilisation of resources, and get a competitive edge in the market with industry specific chemical ERP solution. Contact us to start now.