If you are a process manufacturer across the UK and Europe and need a robust business management software that gives the ability to manage and streamline manufacturing, distribution, finance, quality compliance and all other supply chain activities then BatchMaster ERP for Microsoft Dynamics GP is the right choice!

- Works in a single environment through the same GP interface

- Log-in with the same credentials, and

- Stay connected and informed by working on the same database

The BatchMaster Manufacturing ERP for Microsoft Dynamics GP securely exchanges data between BatchMaster Manufacturing Modules and Inventory, Sales, Purchase of Microsoft Dynamics GP for enhanced experience coupled with the power of formulation, batch processing, product development, material planning etc.

BatchMaster Manufacturing ERP with Microsoft Dynamics GP is useful for all departments at all levels. Thus, process manufacturers across the UK and Europe can take informed decisions faster, improve cash flow, control wastage, comply with regulations, consolidate finances, and increase ROI.

Benefits of BatchMaster Manufacturing for Microsoft Dynamics GP

A Complete solution

It caters to all your process manufacturing requirements. From formulation to R&D, purchase, accounts, sales, to shipping, it manages all.

Minimize customization

The solution is customized for process manufacturers and their sub-industries. This brings the need of customization to minimal.

Cost and loss control

With its amazing features, you can plan, track shelf life of inventory, utilize process cells to the fullest, avoid over stocking, thus reduce cost and wastage.

Increased profitability

By responding to prospects, customers with the right information at right time, you can increase database of happy customers, impacting positively on profits!

Unified system with diversified tools

Various modules works in cohesion to provide real-time and accurate data for better informed decision making.

Meet Compliance

Easily comply with industry standards, best practises, and local requirements, print labels & allergens, attach SOPs, handle hazardous materials, and manage audits.

Better ROI

Faster implementation, timely upgrades, scalability, and adaptability to new upgrades make the setup work faster, smarter and in more efficient manner, resulting better ROI!

Higher Productivity

Familiar working environment, single login, and the same database enable your employees to manage personalised tasks under one roof, hence making them more productive.

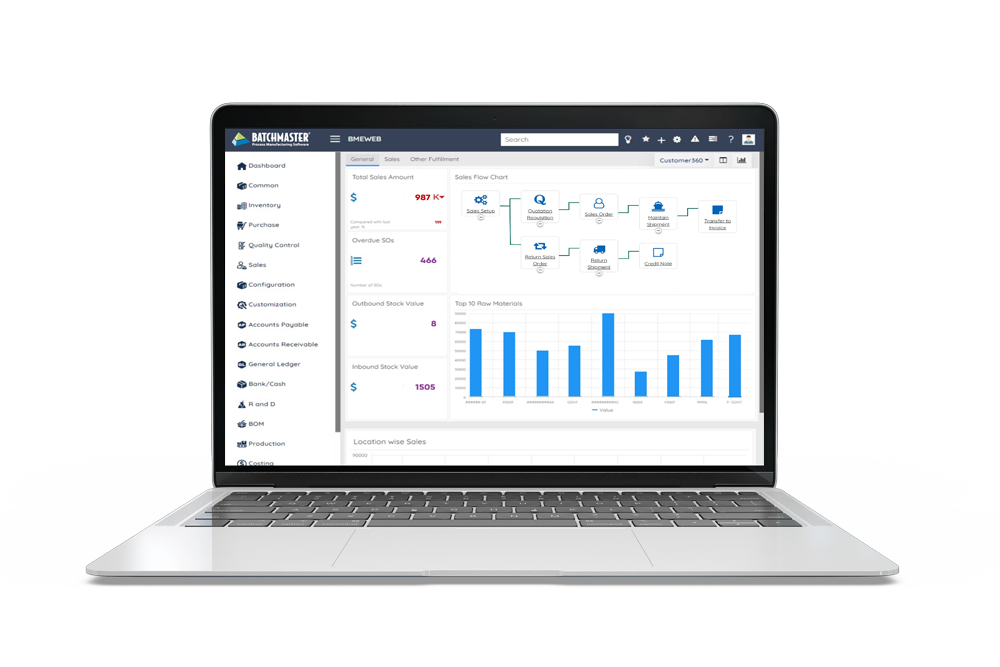

BatchMaster Manufacturing ERP Modules

Formula Management

Manage, with ease, your formulas/recipes taking it from inception through R&D to Production; approving at every stage. Version control and rollback, material substitution, loss and cost analysis, formula sizing, etc. are just a few among the many capabilities provided by BatchMaster Manufacturing.

Cost Analysis

Analyze the costs involved in manufacturing an item with immense ease and zero calculation. Take a back seat as you see BatchMaster doing complete cost analysis separately as well as combined for products & their packaging, what-if analysis, target price achieving, cost comparison and lot more through its Costing module. Analysis is based on Standard, Market, Average, Last Cost and Base price.

Laboratory

BatchMaster manufacturing takes complete care of your intricacies that is your physical properties, giving you the power of speedy calculations, and deeper insights. Multiple equations and physical properties definitions, analysis of physical properties based on target values, comparison of physical properties, and property roll-up capabilities are encompassed in the Laboratory module. Opportunity and sample management are taken well care of along with their efficient tracking and costing.

Production

Utilize the power of advanced models like SuperBatch to accommodate the production of intermediates and finished goods together in the same batch, and BatchWithRuns to allow large all-day batches to be separated into individual executable pieces. Anytime Batch Sizing, batch substitution, BOM sizing, partial and full close, weight/volume and yield analysis, batch inspection, etc., substantially eases today’s complex job order processing.

Compliance and Reporting

Compliance Reporting is made expedient with ‘smart lists’- an out-of-the-box capability that also handles your tracking and tracing needs. Multiple analysis tools and dashboards provide you with deep insights and role/purpose/job-specific information aiding better, more efficient, and timely decisions.

Quality Analysis

End-to-End quality analysis from raw material issue to production, during production, post production, and on the finished goods produced. Associate various tests and expected results supports various result types (pass/fail, numeric, alphanumeric), perform tests and retest with provision for destructive tests and restrict the use of unqualified items.

MSDS

Meet GHS and implement hazard communication programs by means of SDS and reduce the incidence of chemical-related occupational illnesses and injuries. MSDS offers a robust set of features for automatically generating Safety Data Sheets, Labels, SARA Reports, shipping documents, etc.

MPS/MRP

Plan production and purchase based on anticipated demand and supply, through BatchMaster’s MPS/MRP modules. Plan for future productions by establishing the amount of raw materials, labor, and machine required to manufacture a specified number of products considering the various sources of demand and supply, conveniently using MPS/MRP functions.

Integrate. Extend. Excel.

Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

See BatchMaster ERP in Action

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs

BatchMaster Software is one of the market leaders in offering enterprise software solutions for the process manufacturing industries. With an in-depth industry analysis, gained through a vast industry experience with over 2000 implementations worldwide, we clearly understand the unique industry challenges. BatchMaster offers ERP solutions that are apt to support industry specific operations and handles critical processes of the micro-verticals. Process manufacturing companies around the globe have come to rely upon BatchMaster® to manage nearly every aspect of their manufacturing distribution, finance & accounting, Quality Control, Compliance and HR- related operations. With headquarter in Laguna Hills, BatchMaster has its offices in New Jersey, India and New Zealand.