UK Food Industry Trends-

Post-Covid restriction lift-ups, it was difficult for the food manufacturers to achieve the required level of consumer closeness again. The reason is the conscious consumption of processed foods due to the increased trend of healthy eating. But, on the contrary, it can be said that manufacturers have got a new opportunity to re-align their products with consumers’ health-conscious ideology.

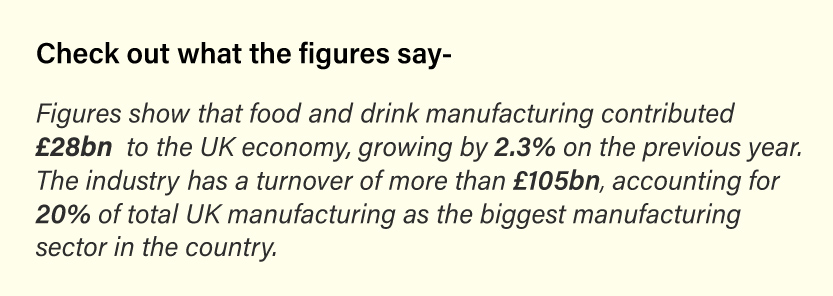

Despite this, in the UK, the food and beverages manufacturing sector still is the largest contributor to the country’s economy, as compared to automotive & aerospace. But, as the whole world is still struggling to emerge from the effects of pandemic, to shape the food industry for a better tomorrow, manufacturers need to address consumer concerns through data-driven and insights-led decisions.

Is The Food Industry Growing in the UK?

When it comes to the matter of economic development, good export is the key contributor to industry growth. The F&B sector in the UK has enough opportunities to expand itself in international trade. As per the reports, sales to the two relevant markets- The United States and China have increased by 11% and 16% in the previous years.

Though this sector contributes around £31.1 bn to the country’s economy annually and has huge opportunities to grow, the industry also becomes critical on a few fronts. As the market is uncertain, it faces challenges including fluctuating consumer landscape, increasing pressures on margins, nutritional needs, mass production due to rising population, etc.

Source- Santander.com

Key Areas of Concern for UK Food Manufacturers-

Adding to these challenges is the impact of Brexit (British Exit) that has imposed trade restrictions between the UK & the rest of the European countries. This has created turbulence in the market by giving rise to a plethora of problems, the prominent ones being:

1. The Increased Competition-

About 30% of all the food in the UK comes from the European Union, according to the British Retail Consortium (BRC) industry group.

Though the withdrawal agreement of the UK with the EU of leaving the union has increased growth opportunities for the local manufacturers, this has incredibly intensified the competition too. To leverage the home country’s advantage, UK manufacturers need to make themselves strong and efficient to compete against the food imported from the EU.

This has marked a genuine need for technologically advanced food manufacturing software that will improve working efficiency by reducing waste and ensuring optimum usage of the resources.

- Sustainability-

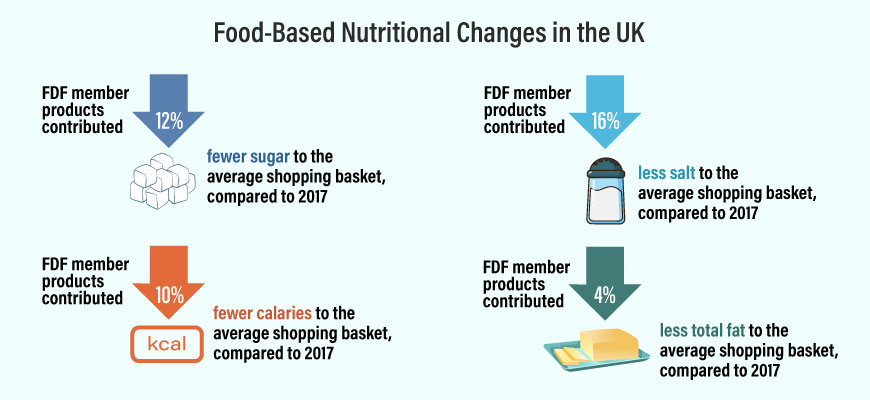

Most of the customers have become concerned about the food they are eating. Instead of getting impacted by the lowest price range, their preference has shifted towards consuming ethical and healthy products. This has opened doors for innovation for food manufacturers which is again an opportunity in disguise, if encashed effectively.

This need of innovating healthier, sugar free, organic products and hit it on market shelves before the competitors cannot be met through paper-based methods but through an ERP that has dynamic R&D capabilities.

Hence, from the food safety point of view, manufacturers need to respond quickly against any food contamination. This can only be achieved with the help of a robust traceability feature of food manufacturing software.

2. The Labor Pains-

The labor shortage has always been a big problem for the food manufacturing industry, which got exaggerated in the COVID times. Moreover, the tightened rules on overseas traveling because of Brexit, outlawed foreign workers from entering the UK. This compels manufacturers to plan their future with fewer people and an increased level of automation in the plants.

Speaking to analysts after Nestlé reported its first-quarter sales, CEO Mark Schneider said the world’s largest food maker could have sold more products in North America if it wasn’t for labor shortages.

Source- www.just-food.com

What is Food Manufacturing ERP?

It is widely known that proper lubrication facilitates uninterrupted working along with less maintenance, less energy consumption, increased production, and improved life of the machinery. Similarly, Enterprise Resource Planning (ERP) is a Food Manufacturing Software that overhauls all the business processes like Manufacturing, Distribution, Quality, Compliance, Inventory management and Finance/Accounting, etc., to ensure flawless production.

The labour-saving functionalities of this business management software boost automation within the organization and eliminates all the manufacturing complexities with its numerous additional features. This technology of managing business processes automatically won’t lose popularity anytime soon.

Importance Of Industry-Specific ERP For the Food Industry-

The tightened industry standards due to growing safety trends have made it difficult for food manufacturers to produce profitably. Moreover, issues like wastage due to contamination, margin pressures, and persisting competition have further fuelled the flames of shrinking bottom-line.

In situations like this, turning to an Enterprise Resource Planning (ERP) software for food to manage the vital processes could clear the way for a succeeding future. As this business management software integrates perfectly with the different aspects of your manufacturing business like purchase, production, inventory, sales, distribution, budgets, etc., and meets every specific need of your business. Keep reading to know how! Also Read: Difference Between A Generic ERP & Industry-Specific ERP

Prominent Features of the Industry-Specific Food ERP In the UK-

Although all manufacturing enterprises share many similarities, implementing an industry-specific ERP for UK based food manufacturing industry benefits differently. This is because it suffices the needs of the enterprises at a detailed level. It Helps in:

1. Managing Formulation-

For food manufacturers, recipe control is of great importance. For this, ERP software helps manufacturing organizations with recipe management for new and existing products. It allows manufacturers to record, edit, compare, and store the recipes to maintain product consistency.

Also Read: What is a Food Formulation Software?

2. Managing Inventory-

In the F&B industry, there is a high possibility of food materials spoilage, if not managed properly. The ERP’s inventory management module smartly deals with the purchasing & planning of food materials to avoid stockpiling & shortages in the inventory.

It also minimizes inventory loss by notifying about the soon-to-expire products and thus saves up on overhead costs too.

3. Managing Compliance-

Due to the significant changes in the last two years the food industry has witnessed tighter safety regulations and stringent requirements businesses must meet. This has made compliance more challenging. In the face of this challenge, ERP software can help manufacturers meet all local and international compliance requirements, along with cGMP norms.

For products like whisky, beef, and various breakfast cereals, it helps manufacturers in printing ingredients labels to stay abreast with all the compliance requirements.

4. Managing Quality-

Maintaining the quality of the manufactured food is crucial to ensure the safety of the customers. The quality assurance feature of food ERP software for the UK can help you set up tests and processes to measure the quality of goods. Its bi-directional traceability feature performs thorough checks while procuring, utilizing, producing, and finishing a batch of products.

Moreover, the QC module immediately responds to any non-conformity or contamination and quickly processes the product recall to minimize the risk and loss.

5. Managing Allergens and labelling-

Continuing with the safety concerns of customers, food manufacturers need to take notice of the ingredients, especially allergy-causing foods. Right from the storage of such materials, every stage of their production must be tracked to eliminate even the smallest possibility of risk.

Proper labelling of allergens, ingredients and nutritional values as per FDA norms is yet another challenge for food manufacturers which can be simply resolved using an ERP software that allows generation of labels in all FDA-specified formats.

Extended Features of a Food ERP Software-

Apart from the above-mentioned functionalities, a food-specific ERP software assists with its additional set of capabilities on the following fronts-

- Material and Package Costing

- Master Production Scheduling (MPS)

- Material Requirement Planning (MRP)

- Supplier/ Vendor Management

- Inspection Planning and Inspection Schedule

- Adverse Event and Complaint Reporting

- Lot Strength

- Catch Weight

- Halal and Kosher Management

- Ingredient Statement and Report

- Corrective Action Preventive Action (CAPA)

- Non-Conformance (NC)Hazard Analysis and Critical Control Point (HACCP)

Benefits of Food Manufacturing Software-

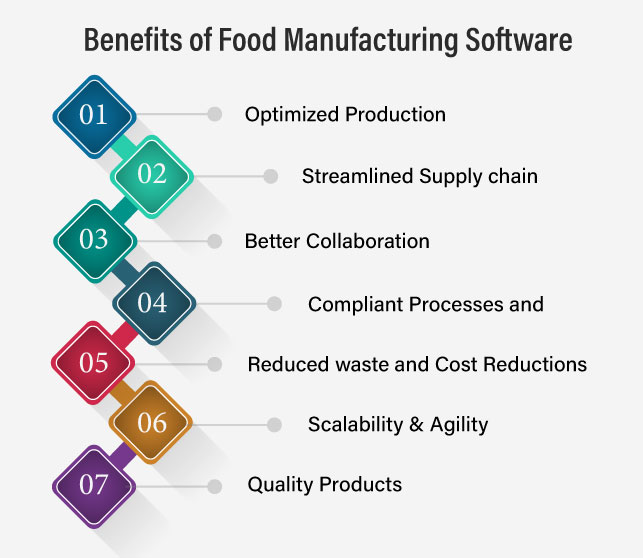

Tackling the complex food safety regulations requires deep insight, visibility, and control over the core operational processes. For this, implementation of a food ERP software helps businesses in multiple ways like manufacturing products as per the current market trends, boosting the R&D process to innovate in no time, streamlining the whole supply chain, optimizing the inventory & production, thus reducing the waste plus increasing profitability. Moreover, it allows manufacturers to control business remotely by offering real-time updates of production, sales, and distribution.

Conclusion-

The F&B businesses with its specific set of challenges discussed here can’t out beat the competition and create a way for success without an ERP software for food. Having an ERP software designed and developed considering their requirements and backed by a solid experience is a sure ticket to profitability and growth. One such solution is BatchMaster Food ERP for Manufacturing Industry in UK that offers an increased set of benefits along with the ensuring standard processes.

Its tailored features like lot/serial management, by-product and co-product management, bills of material, multiple packaging options, cost analysis, and many other things, help enterprises with unique operational potential. Click on the link to contact our team of experts.