Overview-

“According to a report by the UK Food & Drink Federation (FDF) and Santander, the UK Food & Drink sector, which is valued at more than 100 million euros, has a golden opportunity to expand into new markets around the world.”

There are numerous stats, similar to the one mentioned above, that clearly reveal the fact that the UK food manufacturing industry is the largest and the most significant contributor to the country’s economic growth.

Employing around 4 million people, the sector individually generates around 121 billion euros annually, showing that the sector has opportunities for expansion.

However, every sector has its own story and every story has its own challenges, playing the role of “Villain”, that obstructs growth.

In the food industry, contamination issues and the growing foodborne illnesses play that role responsibly.

“According to a scientific review by the Food Standards Agency (FSA), around 2.4 million cases of foodborne illness are reported every year in the UK.”

Such stats give us a better idea of the fact that food plays a vital role in spreading all infectious intestinal diseases.

And this reinforces the need to ensure the highest standards of food hygiene practices in manufacturing.

That’s why “Food Traceability” came into practice.

Let’s move ahead knowing the concept of food traceability in brief.

Introduction to Food Traceability-

Food traceability is the practice that food manufacturers follow, which involves tracking the movement of food products from farm to fork, ensuring that every step, from sourcing ingredients to production and distribution is monitored and documented.

This facilitates manufacturers in preventing the affected food products from reaching the marketplace, ensuring that consumers get only fit-to-eat products.

Food traceability helps in

- Improving Inventory Management

- Staying Compliant to Regulations

- Building a Positive Brand Image

Why Is Implementing a Food Traceability Software Necessary?

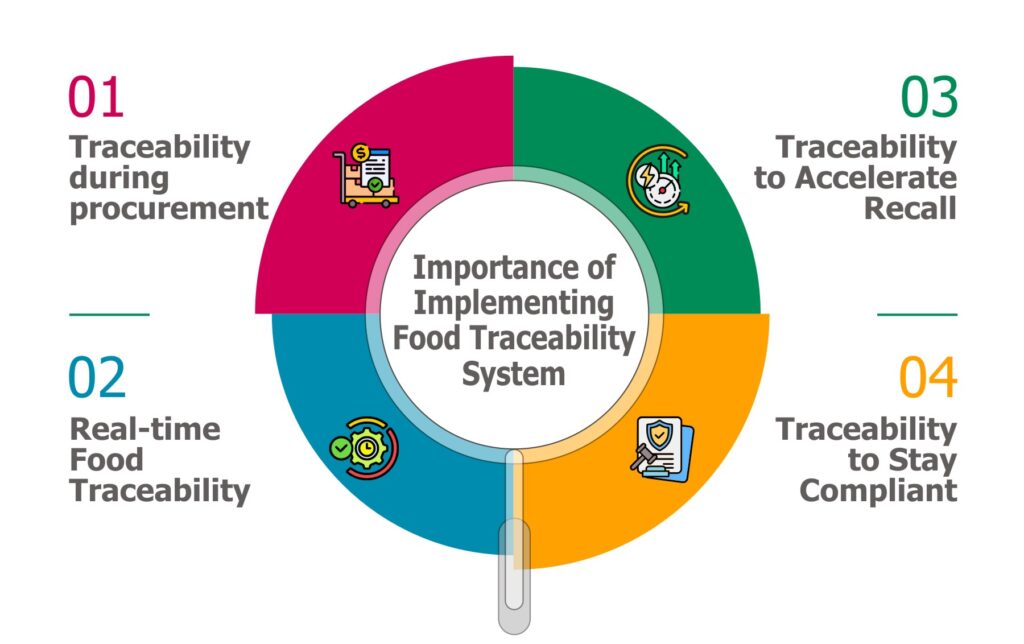

The level of importance of a food traceability system can be noticed through the capabilities it provides at different stages of the supply chain.

Food traceability plays a crucial role in managing safety, quality, and compliance across the supply chain, particularly during critical situations like contamination. When an issue arises, traceability enables manufacturers to track down the source of contamination.

With real-time traceability, manufacturers can pinpoint the exact batch involved, identifying and isolating contaminated products to prevent them from entering the market.

Furthermore, lot traceability module of ERP software support both forward and backward tracking. Backward traceability helps trace a product back to its origins—such as knowing the exact batch or lot in which the product was produced, then the set of raw materials that went into its production, and also the vendor from whom the materials were purchased. This helps identify the real source of contamination.

On the contrary, forward traceability, allows manufacturers to track a material along its journey to becoming a finished good followed by where that finished products have been delivered. This functionality is essential for accelerating product recalls, allowing manufacturers to trace defective items to the stores selling them and call back those lots before they reach consumers.

Both functions are vital for quality control, compliance, and maintaining transparency, ensuring consumer safety while protecting the brand’s reputation.

However, manual execution of whatever functionality we discussed above, is time-killing and error-prone as well. Humans could easily miss out on identifying & isolating the exact contaminated product.

Now in a sector where consumer safety is paramount, failing to pinpoint contamination issues quickly can directly lead to significant financial loss and hefty penalties.

Instead, adopting a food manufacturing traceability software automates all the tasks of tracking and documentation, helping organizations to stay compliant always.

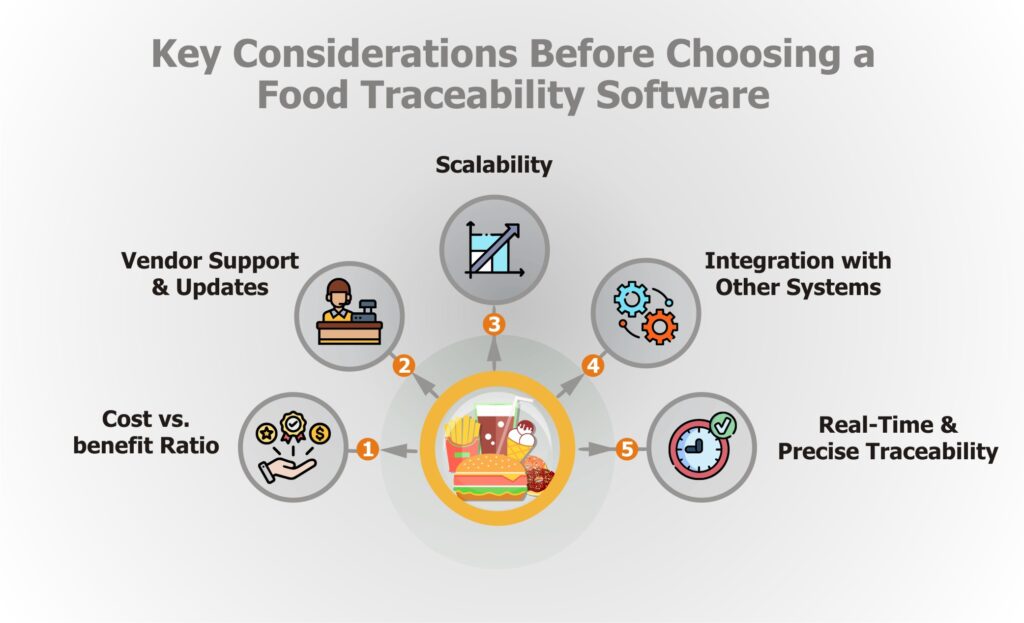

But, before choosing, it is recommended to evaluate the software on certain parameters, ensuring its complete usability.

How to Choose a Good Traceability Software for Food Industry?

Finding the best traceability software for food manufacturing is challenging as well as crucial for ensuring quality, safety, and compliance in the food industry. Here are some tips to help you choose the right solution:

1. Assess Your Specific Needs

- Know the size of your business—whether small, medium, or large.

- Identify what you need to trace such as ingredients, batches, or suppliers.

- Ensure that the traceability feature of the software integrates seamlessly with other modules of the ERP software

2. Compliance with Regulations

- The software needs to meet your region’s food safety and traceability regulations (e.g., FSMA in the U.S., EU Regulation 178/2002).

- It should also support certifications like ISO 22000 or HACCP, ensuring regulatory adherence & building consumer trust.

3. Real-Time Data Access

- The solution you choose should offer real-time tracking, enabling instant access to data across the supply chain.

- Cloud-based ERP systems often offer better real-time access, enhancing transparency & boosting efficiency.

4. User-Friendly Interface

- A system with a user-friendly interface reduces the training time and encourages quick adoption among the team.

- Ensure the system fulfils the needs of different users in the chain, from warehouse staff to managers.

5. Co-ordination

- Ensure that the traceability feature efficiently captures data from procurement, production, and distribution departments.

- The system should be capable of tracing the journey of materials, from their processed batches, to the raw materials used, and down to the vendor from whom it was purchased.

- It should also be capable of tracking materials throughout the entire process—starting from raw materials to intermediate stages, transforming into finished goods, and finally reaching the customer.

- Seamless integration reduces manual work and ensures data consistency.

6. Scalability

- It is recommended to choose a solution that can scale as your business grows.

- The system should be capable of handling increased data volumes, new product lines, and additional suppliers as you expand operations.

7. Data Security

- The sensitive nature of food traceability data demands the software should be equipped with robust security measures.

- It’s beneficial to look for features like encryption, secure logins, and regular backups.

8. Reporting and Analytics

- The system should have the ability to generate essential comprehensive reports on traceability data.

- A software that allows generation of customized reports, tracking trends, and performing audits easily, is considered the wise choice.

9. Mobile Compatibility

- A mobile-friendly system proves highly beneficial for the staff working in the field or at multiple locations.

- Ensure the software works well on smartphones and tablets.

10. Customer Support and Training

- Choose a vendor that offers good customer service, including both online and on-site support.

- Ensure that the company provides training materials and resources to help your team get up to speed.

Get Yourself Introduced with a Comprehensive Software-

Being capable of its specific function, the standalone food traceability software you choose may fail to integrate with other systems of the organization, resulting in inefficiencies and data silos.

On the contrary, selecting a complete package like ERP software for food industry with integrated food traceability features will prove even more beneficial.

This is because food traceability software offers a centralized platform that acts as the bridge connecting all the disparate departments, allowing for seamless communication and uninterrupted data flow across the organization.

However, there are multiple options available in the market but, choosing the one that would be capable of catering to all your needs is challenging.

BatchMaster ERP for Food and beverage Industry is one complete ERP software your organization should have because the best players deserve the best by their side.

Get in touch with our team of experts to know more about it.