In the competitive landscape of the food industry, leveraging the right tools can make all the difference. Food production planning software offers a suite of features designed to streamline operations, boost efficiency, and drive profitability. This guide explores the key features of food production planning software and how they can maximise your business success.

But before let’s brush up basics.

What is Production Planning?

Production planning is a process of planning what, how much and when a product will be produced before manufacturing actually starts. Production planning considers various aspects like resource availability or supply, demand, machines, money, labour, physical space etc.

The primary goal of production planning is to identify and plan the easiest, most cost-effective method of producing a product with desirable quality.

Importance of Production Planning

Since production planning is a well thought plan of production, it helps in:

- Improving efficiency

- Knowing more about resources, and customers’ choices

- Improving customer satisfaction

What is Food Production Planning Software?

Food production planning software is a technological tool designed to optimize the production process within the food industry. It enables precise production scheduling, accurate resource allocation, and efficient planning, helping food manufacturers meet demand while minimizing waste.

By enhancing resource utilization and streamlining operations, this software boosts productivity and profitability, allowing businesses to achieve better cost control and adapt quickly to changing market demands.

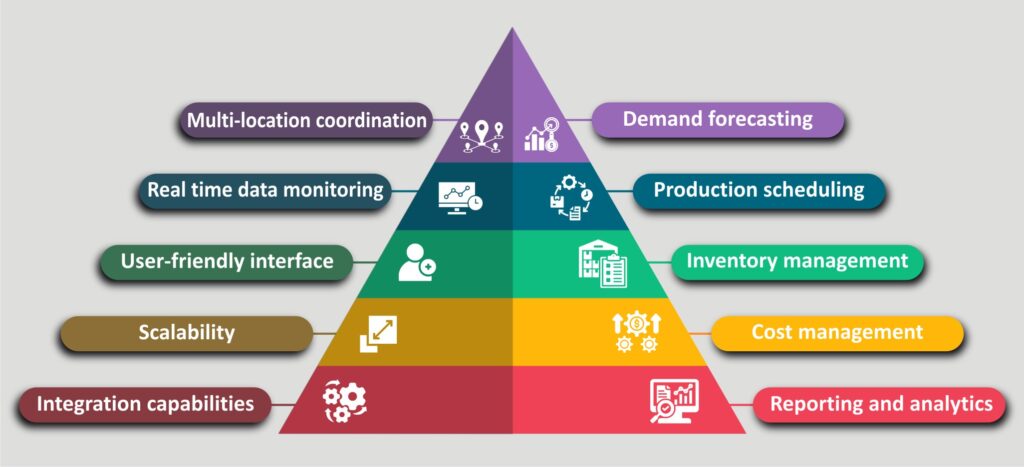

Essential Features in Food Production Planning Software That Help in Maximising Success

There are various essential features that food production planning system must have. Some of these features are:

Demand forecasting

One of the cornerstone features of food production software is demand forecasting. This feature:

- Analyses historical sales data

- Considers seasonal trends and market fluctuations

- Integrates external factors like promotions or events

- Provides accurate predictions of future demand

By leveraging demand forecasting, businesses can optimise production levels, reduce waste, and ensure product availability without overstocking.

Production scheduling

The production scheduling feature is vital for maximising efficiency. It offers:

- Drag-and-drop scheduling interfaces

- Resource allocation optimisation

- Capacity planning tools

- Conflict detection and resolution

- What-if scenario planning

By optimising production schedules, businesses can increase throughput, reduce downtime, and improve overall equipment effectiveness (OEE).

Inventory management

Efficient inventory management is crucial in the food industry. This feature typically includes:

- Real-time inventory tracking

- Automated reorder points

- Batch and lot tracking for traceability

- Expiration date management

- Integration with warehouse management systems

With robust inventory management system, companies can minimise carrying costs, reduce spoilage, and maintain optimal stock levels.

Cost management

Cost is a crucial factor of any production planning. Cost management feature of the software help organisations to

- Track cost real-time

- Monitor ingredient price fluctuations

- Analyse yield

- Calculate profitability per product or per lot

- Help to breakdown costs for better strategies

By closely monitoring costs, businesses can make informed decisions about pricing, ingredient sourcing, and product mix.

Reporting and Analytics

Reporting and analytics play an important role in driving success for any organisation. By analysing the data, and tracking various KPIs, management can take necessary actions which can yield better results.

Integration capabilities

Integration is an important feature in a production planning software. With growing technologies and connected world, the software cannot remain isolated. It can integrate with

- ERP (Enterprise Resource Planning) system integration

- CRM (Customer Relationship Management) connectivity

- Accounting software integration

- Inventory management software

- E-commerce platform connections

- IoT (Internet of Things) device integration for real-time data collection

These integrations ensure data consistency across systems and provide a holistic view of the business.

User-Friendly interface and customisation

A good food manufacturing production software should be intuitive and customisable:

- Ease of use: Drag-and-drop functionality, customisable dashboards, and accessible reporting.

- Personalised workflows: Allow users to customise the software to match their specific business processes.

- Mobile-friendly access: Users can manage production schedules and track progress from their smartphones or tablets.

User-friendly software leads to faster adoption and improved productivity.

Real-Time data and monitoring

Having access to real-time data is crucial for food production planning:

- Live production monitoring: Track production progress in real-time, allowing for adjustments if there are delays or issues.

- Immediate feedback loops: Gain instant insights into production performance and make quick adjustments.

- Remote monitoring: For managers overseeing multiple facilities, real-time remote monitoring ensures everything is running smoothly, even when not on site.

Real-time data allows businesses to be agile and responsive to changing production conditions.

Multi-Location coordination

For businesses operating across multiple locations, production planning software can help:

- Centralised production planning: Coordinate production schedules across multiple manufacturing plants.

- Location-based inventory management: Manage inventory at multiple locations to optimise distribution and reduce transportation costs.

- Location-specific reporting: Track performance metrics for each plant to ensure consistent quality and efficiency.

This helps businesses manage production across different facilities without losing control of processes.

Limitations of food production planning software:

While food production development software is designed to handle specific aspects of the production process—like scheduling, demand forecasting, and resource allocation—it is often insufficient on its own. To manage the entire business process efficiently, food manufacturers typically require additional systems such as:

- Sales Management System

- Financial Management Software

- Procurement Tools

- CRM Systems

Each of these systems operates separately and may require integration with the batch production software to ensure smooth operations. However, managing all these integrations comes with a series of challenges, like:

Increased complexity

Increased complexity

Synchronising data across multiple systems, especially in different environments, is complex. Isolated systems lead to data silos, manual tasks, and costly integrations.

Lack of centralised control

Disconnected systems cause fragmented operations, leading to overproduction, stock shortages, mismatched financial records, and delayed reporting. Managing these systems requires extra resources and slows decision-making.

Reduced scalability

As businesses grow, scaling disconnected systems becomes harder. Updating integrations and making rapid changes is cumbersome without a unified platform.

Then what is the solution?

A Food ERP eliminates the need for multiple standalone systems by providing an all-in-one solution that integrates production planning with other crucial business functions, reducing complexity and improving operational efficiency.

Outstanding Features of Food ERP for Production Planning:

Customisable planning bucket– The software allows to create customisable planning bucket, that aligns with the company calendar. It allows short-, medium, and long-term planning in days, weeks, months, years.

Master Production Schedule (MPS)– This functionality helps to create a manufacturing plan for what to produce, when to produce and how much to produce. It is created by taking sales forecast, planned purchases, production orders, inventory status, work orders and bill of materials in consideration.

Material Requirements Planning (MRP)– This functionality ensures that materials never fall short to fulfil production requirement and material carrying cost is minimised.

The functionality gives a consolidated view of demand and supply. Therefore, once the production plan is confirmed, it can create purchase order depending upon demand from MPS orders, open production batches, sales orders and forecasts.

This way the feature helps to determine what to order, when to order, how much to order and when to schedule delivery of an order.

Flexibility of production type– The Material Requirement Planning (MRP) perfectly satisfies both demand driven and batch scheduling method, making it suitable for both cases.

Pegging– The software allows to perform demand to supply pegging as well as supply to demand pegging.

Hence, in case of demand to supply pegging, for every demand one can have a clear trail of how the demand will be met and which purchase order is fulfilling raw material need against which sales order when MPS is run.

This tracking and mapping allow the organisation to reschedule supplies if there is deviation in delivery date of the order.

Likewise, in case of supply to demand pegging, it maps material supply to meet a particular demand and justifies raw material procurement. Hence, it shows which purchase order is meeting the raw material requirement of MPS order, and finally which sales orders are being fulfilled.

Also, for every client specific need, packing requirements and production job outputs are pegged to each other.

What – if analysis– The software allows to perform ‘what-if’ analysis for production. Thus, it can generate reports of various planning scenarios (like different specifications, plants, process lines etc.) and allows to evaluate and pick the best suited scenario to perform production. Also, this can help to identify shortfalls in other scenarios and fill the gaps for future.

Time-phased production requirement visibility– On the basis of forecasts and demands, the software allows to see required production in time phased manner. In other words, basis forecast and demand data, one can plan the quantity of production in a given time frame. This feature helps in splitting the whole production in chunks, and not producing all in one go, saving over production or underproduction and blockage of money and resources.

Automation– The software automatically converts MPS orders to purchase orders and batch production orders, reducing time lapse and chances of errors in manual conversion. To speed up purchase further, the software consolidates all purchases orders to the same supplier into one order.

Dashboard– The software shows a graphical dashboard of demand and supply data, and all purchase and production recommendations.

Planning Dashboards allow quick access to various data. Planners can create relationships between demand and supply and identify why and when an item is required.

Similarly, with the help of scheduling dashboards, one can evaluate batch jobs created in master production schedule by their groupings (e.g.- priority, items etc.) and review the relationship between their supply and demand factors.

Exclusion– No one wants to consider expired lots in planning calculation. The software is capable to exclude those lots and consider only the one which is good for use.

Schedule MPS/MRP processing– Production is dynamic and keeping a manual check on inventory is next to impossible. At the same time, it is also necessary to ensure that materials and productions are aligned and optimised to meet the deadlines.

The food ERP software allows to schedule processing of MPS/ MRP frequency-wise or calendar-wise.

For example, if MPS/MRP is set weekly, it will run weekly or if it is set on, say the third day of every month, it will run accordingly. This feature ensures that production plans are made regularly as per the demands, and material requirements are checked before production initiates to meet the demand uninterruptedly.

Additional Features That Make Food ERP Software a Preferred Choice over Food Production Planning Software:

Unified Platform- ERP software offers a unified platform for all business functions like sales, finance, inventory etc. This unification facilitates uniform spread of information across departments, enhancing collaboration, communication and reducing confusions.

Scalability- Food ERP offers scope to scale up as the business grows. Hence, it is designed by taking future requirements into consideration.

Customization and integration– ERP software is easier to customize as per your workflows and easier to integrate with other systems.

Automation and digitisation– Food ERP automates and digitises lots of manual and paper based processes, leaving behind the chances of manual errors and saving time and resources spent on redundant tasks.

Easy compliance– ERP system is designed to track compliance with industry regulations like (e.g., FDA, FSMA, HACCP) across the entire business, from production to delivery. This helps businesses stay compliant with minimal effort.

Conclusion

After understanding the benefits of food ERP and knowing about the limitations of food production planning software, one can easily make out that choosing a food ERP software is a better choice to maximise success.

BatchMaster ERP for food is one of the pioneer software among food manufacturing industry, catering to food manufacturers across the globe. Along with above mentioned features, it can provide an additional edge to your production planning with Advanced Planning and Scheduling.

How Advanced Planning and Scheduling (APS) transforms production?

Manage demand fluctuations effectively– APS allows to schedule production on various process cells and change priorities of production with easy drag and drop. This easy and swift adjustments offer flexibility to manage production as per demands.

Adjust scheduling for production- APS facilitates schedule shifting, addition of user defined task and rectification of mistakes of scheduling.

Split Batch– If delivery dates are shifted, capacity bottlenecks occur or raw materials are not adequate to carry out complete batch, Split Batch functionality can split batches and schedule them for quick production.

Colourful dashboard– APS offers colourful dashboard. It allows to assign colour codes to batches as per their status.

These are a few features of APS. Click here to know more about BatchMaster APS.

If you are looking for a production planning software for your food organisation, we’d insist to consider food ERP software BatchMaster ERP and we bet you won’t regret in future.

Please book a demo of BatchMaster ERP for food by writing us on sales@batchmaster.co.in or contact us.