The Re-Rise of the UK Manufacturing Sector

The UK is the birthplace of the Industrial Revolution and continues to proudly hold the title of being a leading manufacturing nation. However, by the end of 2023, the UK manufacturing sector ended on a weak footing, struggling and surviving amidst numerous challenges post-pandemic.

Later, the manufacturing industry rebounded quickly and is currently in a much better position. However, challenges related to the supply chain and a skilled workforce remain unchanged.

Among these challenges, geopolitical limitations like Brexit stand out as the most prominent, restricting the flow of materials. This creates a tough-to-navigate situation for UK-based manufacturers who struggle to receive materials on time, ensuring uninterrupted production.

Moreover, the UK manufacturing industry operates within complex supply chains involving numerous suppliers, subcontractors, and logistics providers. Managing such a long chain manually becomes a daunting task, resulting in inefficiencies and delayed material deliveries.

This highlights the need for robust technological support to build a resilient supply chain, ensuring the right quantity and quality of materials at the right time. This could help increase the speed of production.

That technological support is a Material Resource Planning (MRP) software.

This blog will help you dig deeper and demystify the clouds around MRP software in manufacturing, revealing all its peculiarities along with the features it offers. So, let’s start by understanding MRP software in depth and how it provides magical benefits to manufacturing organisations.

What is an MRP System and Why is there a need to implement it?

Imagine a scenario where, in a manufacturing facility, the production manager relies on manual inventory tracking and ordering processes. However, one day, as a scheduled production run is about to start, the production manager realises there are insufficient raw materials on hand.

Now, placing an order at the eleventh hour won’t get him the required materials on time due to the longer delivery time. As a result, the scheduled production will come to a halt, delivery targets will be missed, customers will be dissatisfied, and revenue will be lost.

If accurate material needs had been identified and inventory levels had been optimised earlier, this loss could have been easily avoided. This is where a Material Requirement Planning System (MRP) fills the gap by ensuring materials are available on hand when needed.

Understanding the Term MRP by Definition

An MRP System, or Material Resource Planning software, is a critical tool in the manufacturing industry, aimed at precisely identifying how much and when materials are needed for production.

Its primary goal is to ensure the on-time availability of materials, preventing manufacturing organisations from experiencing long production halts and productivity losses due to inventory insufficiency.

The MRP software empowers manufacturers with enhanced inventory oversight and production planning capabilities, facilitating efficient production scheduling and resource allocation.

Four Major Steps of MRP Software for Manufacturing

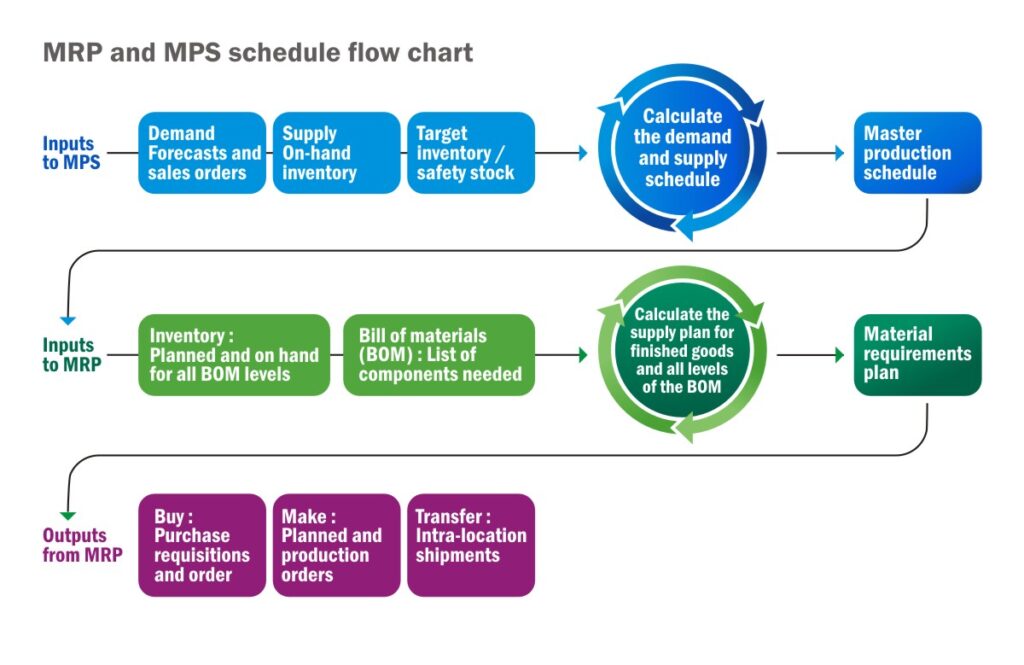

The MRP process can be broken down into four major steps:

1. Identifying Requirements to Meet Demand: What streamlines a production process initially is the Bill of Materials (BOM). It is a hierarchical blueprint or comprehensive list of exactly what goes into producing each unit. This includes the materials required to produce a specific finished product and becomes the requirement.

2. Checking Inventory and Allocating Resources: The MRP system helps you check inventory against the demand you need to fulfil. It facilitates determining the amount of stock available on hand and the location in the warehouse(s) where it is kept.

This is especially beneficial when you have inventory stored across several locations. It also provides visibility into the items already allocated for production, as well as the items in transit and in purchase orders.

3. Data from Master Production Schedule (MPS): The MPS system provides the production schedule that the MRP system uses to determine the material requirements precisely. It also identifies the machinery and workstations needed for each step and generates work orders, purchase orders, and transfer orders accordingly.

4. Lead Time Data Calculation: The lead time data provides information about the time it takes to procure materials from suppliers and the time that will be consumed in producing these products internally. This helps organisations calculate when materials need to be ordered to match the production schedules.

Benefits of a Material Resource Planning (MRP) Solution

- Helps businesses fulfil customer orders on time.

- Eliminates the need for manually fetching inventory data.

- Reduces inventory costs.

- Minimises the risk of stock-outs.

- Improves labour productivity.

- Increases manufacturing efficiency. – Promotes effective allocation of inventory materials.

Conclusion

From the above discussion, it is clear that an MRP system is of great importance for the efficiency, effectiveness, and profitability of manufacturing operations. Without having the right raw materials on hand, manufacturers would fail to keep up with the market demand for products.

However, the ever-growing market demand and competitiveness in the industry require MRP systems to be more capable and competent. That’s why MRP systems are evolving, taking advantage of new technologies like Machine Learning (ML) and Artificial Intelligence (AI), developing even better plans and schedules.

Moreover, adopting Industry 4.0, i.e., the Industrial Internet of Things (IIoT), involves smart sensors and devices that can monitor and control anything throughout the entire supply chain.

If you are also a manufacturer and want to streamline your production by ensuring effective Material Requirements Planning, adopting a comprehensive solution like BatchMaster ERP is the right choice to make. Get in touch with our team to know more about the implementation process.