“Inventory has a direct relation with money and money is directly related to existence of business in the market. Especially when it comes to food industry, inventory can make a huge impact on the existence of a company. A successful food business manages its inventory so promptly that it creates happy customers who become brand custodians.“

“If you are a food manufacturer and wish to transcend your business to such height, stay till the end of the blog to know everything about inventory and its management in food industry.“

Food industry touches every part of the world. Varying eating habits, exposure to world cuisine, growing health awareness and increasing environmental concern of people make the food manufacturers to continually procure newer, greener and innovative ingredients. This makes it challenging for them to have the right inventory to all consumer needs.

Also, managing such a varied inventory is very tiresome and head spinning task for an inventory manager.

In such a scenario, inventory managers relying upon manual and paper-based processes struggle even more. They miss out timely inventory count, prediction, and most of the time these data are erroneous, resulting in total chaos and losses in terms of raw material or opportunity.

Thus, they need a smart solution, like food manufacturing inventory management software.

This blog will elaborate inventory, its management and the use of food production inventory management software to effectively mitigate inventory-related challenges.

If you are a food manufacturing organisation, or an inventory manager in a food manufacturing company, read the blog till the end because this piece of content can really help to make your work easier.

What is Inventory Management?

The process of keeping a track and managing all the goods a company has in stock is known as inventory management.

In case of food manufacturing, all the raw materials and finished goods that the food manufacturing organisation stores in warehouse can be counted as inventory and its management is termed as inventory management.

This is done by an inventory management software for food industry, usually an ERP like BatchMaster ERP for Food, which helps record and track inventory levels along with their procurement, movement, storage and sale.

Type of Inventory –

For a food manufacturing industry, inventories are raw material, sub-assemblies (WIP), finished goods, transit inventory, buffer inventory, anticipatory inventory, decoupling inventory, and cycle inventory.

Let us dig a little to understand these terms better.

Raw Material –

These include material used to produce intermediate and finished goods.

For example, for a biscuit manufacturing industry, raw materials can be wheat or wheat flour, salt, sugar, etc.

Work-in-progress (WIP) –

WIP are intermediate inventory, which is under the process of turning into finished products.

Continuing with the same example, WIP inventory is the dough made after mixing raw materials.

Finished Good –

The product which is ready to be delivered to the customers.

Once dough is processed, biscuits are prepared and packed they are now finished goods.

Transit Inventory –

Transit inventory is inventory that is in transit. After receiving, such inventory rest in warehouse.

Buffer Inventory –

It is additional inventory kept to balance fluctuation in demands. By having buffer inventory, organisations minimise the possibility of stock outs for smooth business function.

Anticipatory Inventory –

Based on past market trends, expected surge in prices or deficiency of materials, if businesses invest in some stocking, then such inventory is known as anticipatory inventory.

Decoupling Inventory –

It is the term used for extra inventory kept at each production line station to prevent stoppages.

Cycle Inventory –

It refers to inventory ordered in optimal lots to minimize storage and carrying costs. In other words, this inventory helps balance carrying and storage expenses, thereby optimizing the overall ordering cost.

Irrespective of inventory type, food and beverage inventory management software eases out management of different items with easy tagging, classification, and item analysis.

Aim of Inventory Management –

On a macro level, there are 4 common goals of food inventory management, these are:

Improvement in production accuracy and order fulfilment cycle-

The food manufacturing inventory management software provides exact data of available inventory for order fulfilment. Basis this data, manufacturers can take decision to either run production cycle, order material, or fulfil order with the on-hand inventory.

Optimised use of space by keeping inventory organised-

The inventory management module of ERP software helps in organising inventory by sorting it on various factors, applying QC before allowing inventory in and facilitating bin transfers, if required.

It also handles inter-warehouse transfer or intra- warehouse movement very effectively.

Cut down waste-

The software helps issue items in inventory as LIFO, FIFO, and expiry. In case of perishable items, (which is the case of food industry) FEFO method is widely used. Hence, the inventory which is nearing expiry will be processed and consumed on priority.

This cuts down the wastage.

Save time and money by lowering production time

Production time is a critical factor in determining resource consumption, which directly impacts the overall cost of a product. Effective inventory management allows organizations to streamline operations, saving both time and money. This efficiency ultimately leads to a reduction in production costs, boosting profitability while maintaining quality.

Why is Inventory Management Important?

Inventory management decides the viability of your business. Inventory can be an asset or a liability, depending upon how you manage it.

Mastering inventory management will let you reap many benefits:

Create happy customers-

Impatient and choosy! That is the trait which most of the customer’s exhibit in today’s world. Catering to such consumers require a well-managed inventory. Only the businesses that manage their inventory meticulously can remain in the race of taking the market share. They can foster customer’s delight and rope in new consumers by prompt service and order fulfilment.

With food ERP like BatchMaster ERP for food, processes like inventory identification, its staging, picking/packing/shipping become faster.

Such fast processes within the organisation eventually make faster deliveries and bring smile on the face of consumer.

Increase productivity-

Effective control on inventory will reduce time and cost involved in manual inventory tracking, which most of the time is erroneous.

By managing inventory effectively, businesses can invest time in other useful and productive work.

Reduce costs–

A managed inventory tells business owners about fast moving inventory, and slow-moving items. This information helps organisations to plan procurement and reduce overstocking which requires immediate investment.

Besides money required for stocking, overbuying also demands storage costs. With well managed inventory, all these costs can be reduced, and the liquid money can be used on business growing activities.

Various inventory reports of BatchMaster ERP help to identify the fast sold goods, generate inventory cost for analysis, and plan procurement with precise requirement.

This planning helps to avoid overstocking, or understocking.

Besides, the software helps to stock seasonal items, suggest economic order quantity, and track co-product and by-product during production.

Foster growth –

Well managed inventory fosters growth. Such managed inventory help organisations to respond to the demands in time and add new product line to the range well before their competitors.

Inventory Management Techniques-

As crucial inventory is, so are the numerous ways of managing it. These techniques ultimately impact the bottom line of a business.

Just in time (JIT) –

This inventory management technique aims to fulfil the demands exactly when it is generated, also known as zero inventory. It reduces waste, overstocking, and improves profits by maximising inventory turnover.

Economic order quantity (EOQ) –

This method is based on the principle that businesses should purchase the optimal quantity of inventory to minimize costs related to storage, ordering, transportation, and other associated expenses. By determining the precise order quantity, organizations can reduce inefficiencies and manage their resources more effectively.

Safety stock inventory-

It stores just ample amount of inventory before stock dry out. It protects stock outs and serves as a cover supply against unexpected demands.

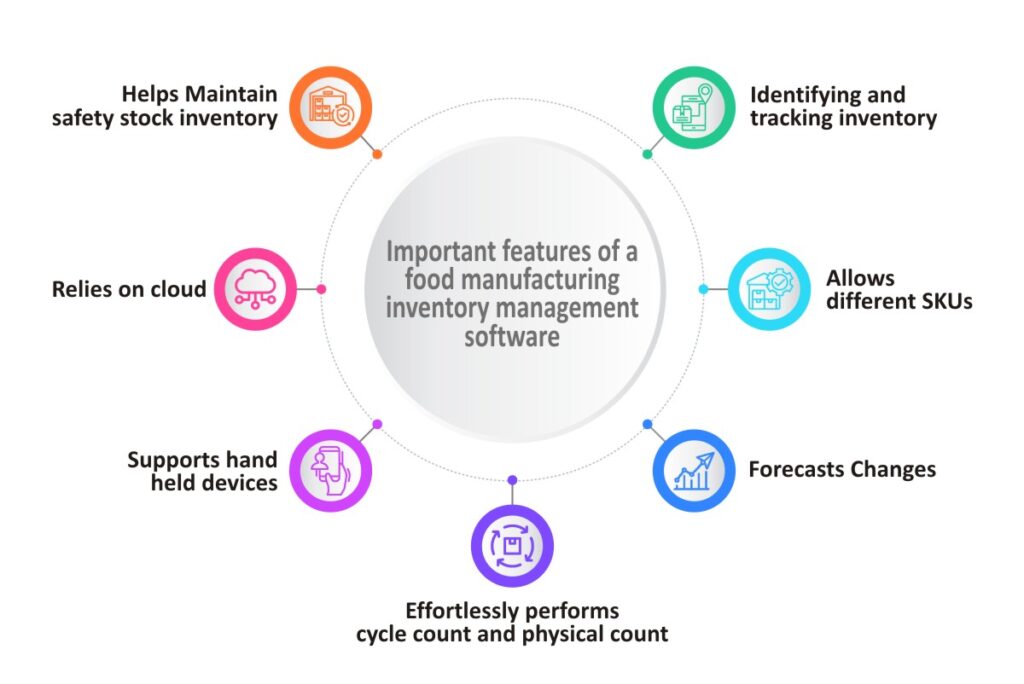

Important Features to look for in a Food and Beverage Inventory Management Software:

There are multiple features that a food manufacturing inventory management software must have. Some of them are:

Identifying and tracking inventory

The software must facilitate tracking and identifying inventory lying in warehouse. The facility helps to select and pick inventory fast so that order-to-dispatch time can be minimized.

BatchMaster ERP for food lets define unique ID numbers that can be assigned to each product variation. This helps segregating various products and collecting it fast when an order is generated.

With the help of the software, you can assign bin number, UID and attributes, and then assign these inventory items to specific bin location. Besides, it helps associate an item with:

- Warehouse or location

- Costing Methods- Last, Average, Standard, Market, etc.

- Tracking Method- Serial, Lot Method

- Lot Issue method- LIFO, FIFO, FEFO

- Classifications such as ABC analysis

- Lot attributes/characteristics

- Tracking at Pallet, Bin, lot to serial level

Allows different SKUs.

Since food manufacturing unit has various materials in different physical state, the industry software must allow various SKUs.

BatchMaster food manufacturing ERP allows defining various unit of measure in terms of Weight, Volume and discrete.

It allows storing in one unit, buying in other and selling in complete third unit.

It even allows one click conversion of one unit to other at all levels- inventory, production or shipping, thereby saving manufacturers from a lot of manual calculations and associated errors.

Forecasts Changes

Aligning the production according to changing consumer preferences is very tough. A food manufacturing inventory management software should be able to track new trends and make changes as per the current and expected demands to assimilate changes.

ERP sofware for Food does that meticulously. It offers various reports that show the fast-moving inventory and slow-moving inventory. Reports also tell about the seasonal demands and basis past data, organisation can plan their inventory.

Effortlessly perform Cycle and Physical Count:

The software must be able to identify the gap between inventory data on computers and actuals. To do this, it must have ability to perform cycle count without impacting the other functions of the organisation.

BatchMaster ERP offers Physical and cycle count that can adapt to your Physical count method and streamline every step of it.

Starting with the segregation of inventory to be counted, generation of tags, tallying of perpetual and physical inventory, restricting any transactions from being executed during the count-in-process and lot more.

Supports handheld devices:

When inventory volumes are low, manual processes like tracking counts in a spreadsheet or diary can suffice. However, for large organizations with high inventory volumes, this method becomes inefficient. This is where handheld devices integrated with inventory management software come into play, streamlining the process and saving both time and effort.

BatchMaster ERP supports a wide range of handheld devices for scanning inventory, significantly reducing the need for manual data entry. It eliminates the hassle of hundreds, or even thousands, of keystrokes, greatly improving accuracy and efficiency.

The inbound and outbound transactions happening in the warehouse can be recorded right where and when they are happening, always giving a real-time view inventory to all the concerned departments.

Relies on cloud-

Cloud-based technology help you to manage business from anywhere, anytime. It can be an effective technology to combat various inventory management related issues.

BatchMaster offers cloud-based ERP solution. Coming as a SaaS model, the solution is budget friendly and offers mobility.

This cloud-based ERP is highly secure, safe and comes with 24*7 customer support and regular backups.

Safety stock inventory-

As previously mentioned, it enables to maintain an adequate inventory level, ensuring that they have just enough stock on hand before running out.

It prevents stockouts and serves as a cover supply against unexpected demands. An inventory management software must be able to support and prompt for safety stock so that there is stock in-hand and thus no situation of production halt.

BatchMaster ERP for Food manufacturing supports it by:

- Setting Reorder Point (ROP) – This is the set level of inventory, below which an alert is generated for re- purchasing the item.

- Reserving inventory lots– The software always gives an alert before using safety stock.

- Defining EOQ.

Conclusion

Success of a business largely depends upon the effectiveness of its Inventory management. There are various solutions available in the market that aim towards proper inventory management, but the most effective solution is a food ERP.

An ERP not only helps to meticulously manage inventory, but it also facilitates quick decision making, compliance to various regulations, automation of various redundant processes and saving resources.

One such food ERP software is BatchMaster ERP. Besides inventory management, it provides numerous benefits that a manufacturer can leverage to manage not only inventory, but various business activities.

Along with above-mentioned functionalities and uses, there are many more that BatchMaster food manufacturing ERP software can offer, like new product development, formulation, costing to get market viable cost of the product, nutritional labelling, Halal, Kosher, allergen management etc.

Your food manufacturing industry will get the best technological ally in the form of BatchMaster ERP. To book a demo, mail us at sales@batchmaster.co.in.