Overview-

It won’t be wrong to say that currently, the UK Food Industry is experiencing a strong wave of insolvency. Inflation has achieved the tolerance limit and soon it will go beyond breaking the level that hasn’t been seen for decades. This is not just a statistics-based theory, households in the United Kingdom are experiencing a significant fall in their daily living standards.

It has been seen that around 91% of the households in the UK revealed that their cost of living has increased, which they have specifically attributed to food, electricity, and fuel costs. These rising prices clearly reflect the challenges food businesses are facing.

Many domestic and international factors are affecting the food production here. The sector, which used to be called the most fundamental to the UK economy, unprecedentedly is coming down and is struggling to keep pace against all odds.

The Challenges-

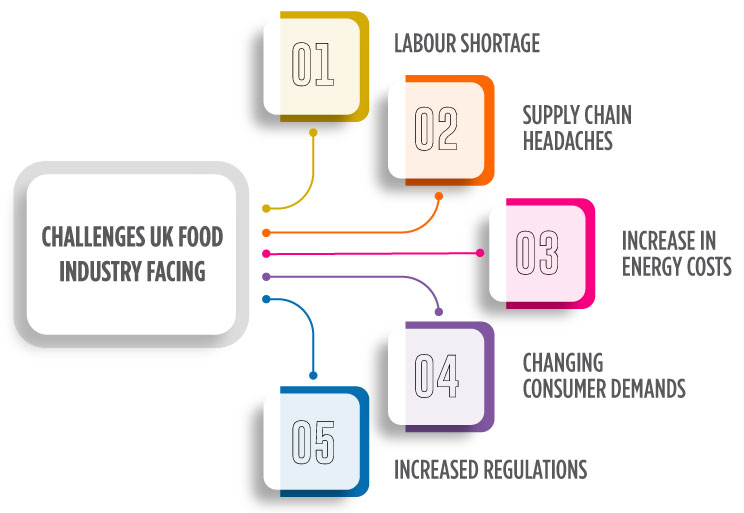

Intrinsically, it is well-known that the food industry, because of several reasons, such as the threat of contamination, bottleneck of transport capacity and efficiency, unbalanced supply and demand, etc., is vulnerable in itself. In addition to this, a few underlying issues, that will be discussed here, have made food manufacturers to trade under a perfect storm.

However, the potential of this sector and future projections ensure a promising future if paint points are identified and resolved. Let’s get to know what are those challenges that are proving to be the main indicators of this downturn.

Labour Shortage-

Getting suitably skilled labor for the food industry has become the biggest issue. In some measure, this labor shortage is linked to the pandemic—the workers left the UK and never returned from their home countries since then. In addition to this, the Brexit policy also tightened rules on workers coming from foreign countries.

This includes logistics too, which requires heavy goods vehicle drivers too, as most UK manufacturing companies import raw materials from abroad and export their finished products to other countries.

Also, for the laborers who are not associated with Brexit, the food industry is not in a position to pay them more than the average living wage, for the increased pay would directly erode the already pretty thin profit margins of the manufacturers.

Supply Chain Headaches-

On an average, around 4 million people are involved in managing the long food-chain from farm to fork. But, because of the border conflicts with the EU countries, these international supply chains with the countries like Northern Ireland are under heavy pressure of strict customs, extensive regulatory checks, and copious paperwork.

This inconvenience forces the UK manufacturers to deliver their foods paying additional costs. Now, it would depend on the manufacturers whether they absorb this additional monetary load or pass it on to their customers.

Increase In Energy Costs-

While inflation is crossing limits across the UK, an unprecedented rise in energy prices is putting a dramatic impact on the food industry. This is troubling the manufacturers in keeping down the already inflated prices for consumers. Moreover, gas-intensive businesses (like Co2 is used for packaging purposes) are struggling with their exorbitant energy bills and bracing for the future after a significant increase in gas prices too.

Owing to this, businesses have now attained the limit of bearing this acute inflationary pressure and hence, need to transform their energy source. Although there are ample options for the food manufacturers to shift their energy source to, such as power from waste, nuclear energy, solar energy, hydrogen gas, etc., but all these strategies are long-term that will take years to get implemented and yield desired results.

Changing Consumer Demands-

After covid, there has been a noticeable change in the choices and demands of consumers regarding food. Studies reveal that 1 out of 5 people expresses a food-related concern in the UK with, the nutrition content in the diet, the price of food, and food waste being the prominent three concerns. But, this move which seems positive and healthy from the customers’ view, could be a challenging one for the manufacturers during such harsh times.

Moreover, to stay in the long run, manufacturers must satiate not just the taste-buds but concern-buds too, by being gluten-free, nut-free, dairy-free, and allergen-free, and such. This means that food companies need to realign their working strategy and existing setup to create room for multiple production lines—making themselves self-sufficient to fulfill these demands.

Increased Regulations

The trail of challenges doesn’t stop here. Even if manufacturers succeed in conquering all of the above-mentioned challenges, one that still remains in the bucket is following the “safety regulations”. As catering to the new consumer demands would require new ingredients and products in the processes, which will directly result in new regulatory developments that manufacturers need to comply with.

Amidst such unfavorable situations, it’s a daily challenge for UK manufacturers to remain compliant with the number of upcoming safety guidelines and regulations. A tempering to it is significant changes in the labeling requirements done by the government-certified regulatory bodies, due to Brexit.

Now the issue is that the UK consumers have become acquainted with the new labeling laws, and hence, food manufacturers are bound to ensure that all the UK labeling requirements are also present on all food packaging.

Action Needed-

The evolution of the food industry is imperative, and the future holds numerous opportunities to thrive and win. It’s simply up to the manufacturers how they adapt and maintain pace with the changes that are happening in the industry.

Despite the presence of such ominous challenges, companies should find the silver linning in the clouds. Companies should take this as a growth opportunity, hustle and bring business transformation.

First and the most important step towards it is adopting automation that could fight labor shortage, save time, minimize waste and ensure optimization of resources. And, automation in food businesses can be realized with the help of Food ERP Software..

However, the current circumstances suggest that instead of choosing solutions that would take long times to implement and come into effect, it is wise to go for one that comes in action pretty faster and is light on the pocket- a Cloud or may be a Web based ERP. This will help mitigate the impact of existing challenges and add up significant profits in their kitty, early.

Now if your mind asks which solution to choose? The answer is BatchMaster ERP for Food.

BatchMaster Can Help-

This robust Food ERP software helps food manufacturing industries to mitigate the impact of inflation by helping organizations run at maximum efficiency and produce safe products—adhering to the changing industry norms.

Offering a comprehensive platform, this food and beverage management software plans precise manufacturing and procurement schedules, keeps the supply chain robust and agile, provides actionable insights, enables traceability, checks quality, helps adhere to regulatory, GMP and labelling laws while also managing finance & accounts precisely. Get in touch with the team of experts today and schedule a demo.