Overview: What’s in the UK’s Food Manufacturing Store for 2025?

As food manufacturers step into the new year, one pressing question remains: How can we stay profitable and competitive in such a dynamic business environment?

With consumer demands for tasty yet healthy food options on the rise and expectations for year-round availability of seasonal products growing, manufacturers must adapt. Simultaneously, rising energy prices are driving up operational costs, and solutions such as reducing pack sizes or sourcing cheaper ingredients often compromise quality, potentially damaging a brand’s reputation.

To remain sustainable in the long term, food manufacturers need to optimise costs and improve operational efficiency without compromising product quality.

Challenges UK Food Manufacturers Will Face in 2025

Compliance with Regulations: Adhering to Food Standards Agency (FSA) rules and post-Brexit trade regulations, including maintaining documentation for imports and exports, will require robust traceability and quality management systems.

Increasing Consumer Demands: The demand for healthier, sustainable, and tasty food options is pushing manufacturers to innovate and adapt.

Sustainability Practices: Meeting sustainability targets while maintaining profitability will be challenging, particularly with rising production costs.

Geopolitical Tensions: Global instability will continue to impact ingredient availability and costs. Manufacturers will need to diversify suppliers and explore local sourcing options.

Labour Shortages: Brexit-related restrictions and a declining UK workforce will contribute to ongoing labour shortages.

Import/Export Guidelines: Continued changes in ingredient sourcing and labelling due to import/export restrictions will require constant monitoring.

Managing routine operations without errors is becoming increasingly complex on a large scale. This is where technology plays a pivotal role. Food ERP software is essential for managing complexities, boosting productivity, and reducing errors.

Current Benefits of Food ERP Systems

- An integrated platform for collaboration and communication across departments.

- A unified database for real-time, data-driven decision-making.

- Real-time insights into business operations for smarter decisions.

- Integration with third-party apps such as financial software.

- Efficient production planning, scheduling, and monitoring.

- Real-time inventory tracking for accurate stock management.

- Seamless management of finances, budgets, and reporting.

However, with the ever-evolving landscape of food manufacturing, ERP software must also evolve to address the new challenges of 2025.

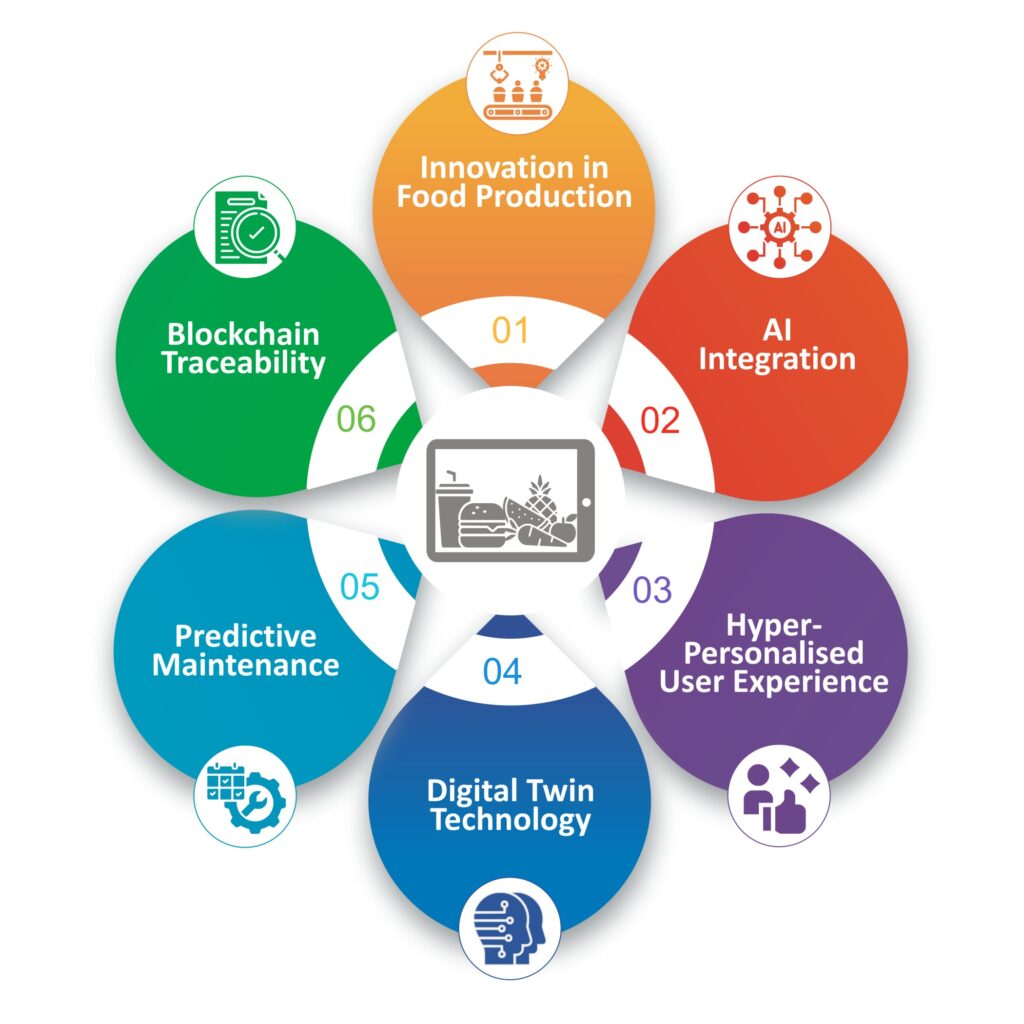

What’s New in Food Manufacturing ERP Software in 2025?

Innovation in Food Production

Consumers are increasingly demanding health-specific, allergen-free, and dietary-specific food. To address this, ERP systems will feature advanced R&D and recipe management capabilities, allowing manufacturers to efficiently meet these needs. Enhanced what-if analysis will enable experimentation with ingredients, substitutions, and nutritional profiles to create customised products.

AI Integration

Data-driven decision-making is now essential in food manufacturing. ERP systems in 2025 will seamlessly integrate with AI to help manufacturers analyse vast amounts of data, recognise patterns, and gain actionable insights to improve operations. AI-powered robotics will automate repetitive tasks, such as packaging and sorting, boosting efficiency and reducing costs.

Hyper-Personalised User Experience

Expect more intuitive and customisable ERP interfaces. Dashboards tailored to different user roles will ensure smooth navigation and task execution.

Digital Twin Technology

In 2025, ERP systems will incorporate Digital Twin technology, enabling manufacturers to create a digital replica of their supply chain, including suppliers, production lines, warehouses, and distribution centres. By analysing these replicas, inefficiencies can be identified and addressed before the final production process.

Predictive Maintenance

Powered by IoT sensors, ERP systems will include predictive maintenance features. This technology will monitor equipment health, identify potential faults before disruptions occur, minimise downtime, and ensure continuous production.

Blockchain Traceability

Blockchain integration will enhance traceability and security in ERP systems. This technology will structure data into tamper-proof digital blocks, allowing manufacturers to:

- Track raw materials to their source.

- Manage product recalls more effectively.

- Ensure compliance with regulations.

- Prevent counterfeiting.

Final Thoughts

The year 2025 brings fresh challenges and opportunities. As consumer expectations grow, food manufacturers must find innovative ways to meet these demands while ensuring profitability and sustainability. To remain competitive, manufacturers must digitise their operations using the best Food Manufacturing ERP software available.

When it comes to leading the way, BatchMaster ERP for Food Manufacturing consistently tops the charts. Contact us to start now.